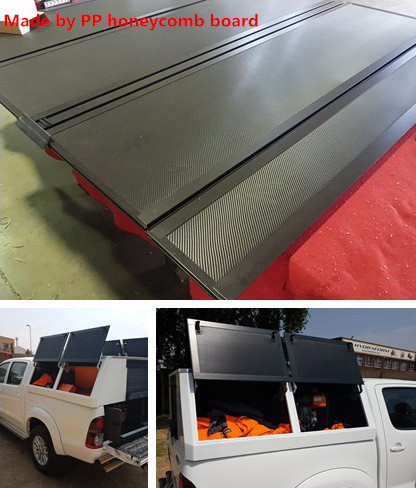

Search This Supplers Products:China manufacturer lightweight plastic corrugated sheets for sign and packaging boxesChina manufacturer good impact strength lightweight pp honeycomb panel for van lining pallet boxChina manufacturer durable plastic pallet container sleeve packs logistics turnover packagingChina manufacturer thermoplastic TPO sheet for automotive floor mats trunk mats truck bed matsChina manufacturer thermoplastic ABS sheet for thermoforming vaccum forming injection moldingChina manufacturer corrosion resistant PP sheet HDPE sheet for chemical industry and aquaculture

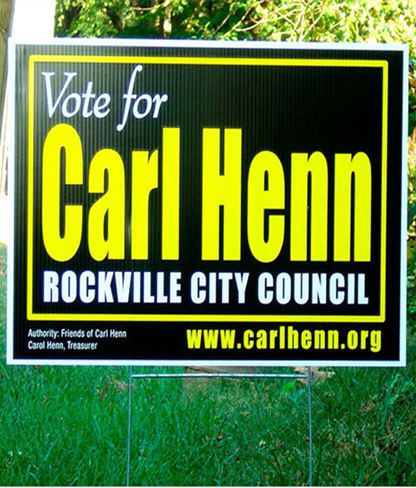

Can the plastic corrugated sheet, honeycomb board and X-shaped board be used outdoors?

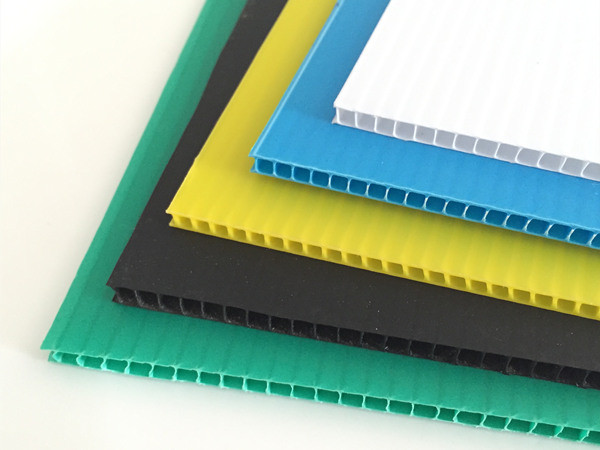

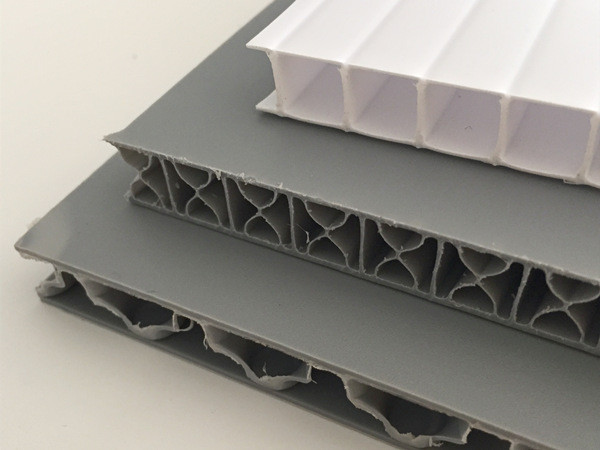

Outdoor used material --- plastic corrugated sheet, plastic honeycomb panel and X type twin wall hollow sheet.

Firstly, we have to know the local outdoor used conditions for PP hollow sheets.

1. Intensity of sunlight (annual average UV exposure, continuous data for at least 10 years) .

2. Moisture and annual precipitation.

3. The lowest temperature.

Secondly, what is the service life of PP plastic hollow board?

Generally speaking, PP hollow sheet is used for advertising, truck body, construction, and other areas, the life span depends on the conditions of outdoor used and product application.

Under the condition of strong ultraviolet rays, heavy precipitation, humid and the lower temperature, the aging speed of PP hollow sheet will be faster.

PP hollow sheet will lose its original properties by light, heat, moisture, and other factors.

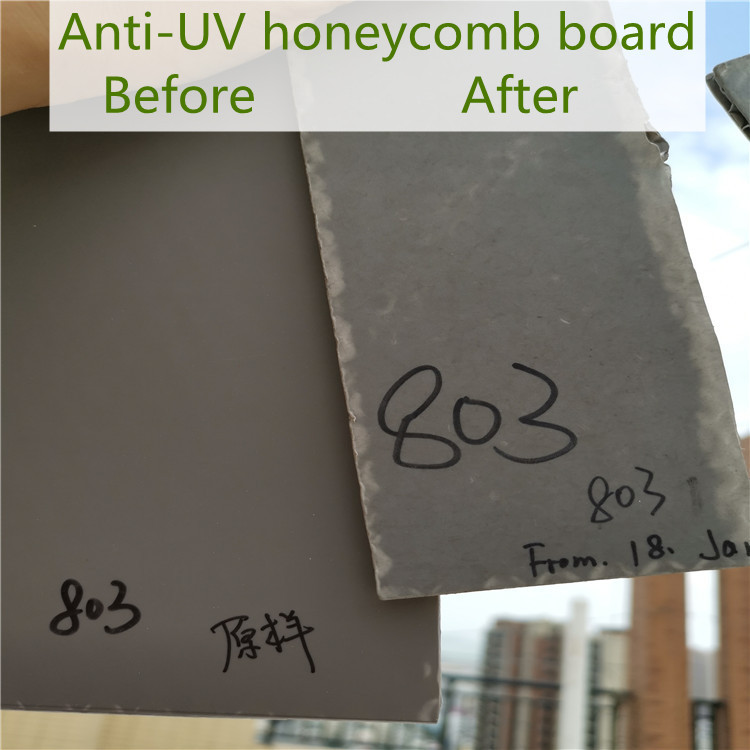

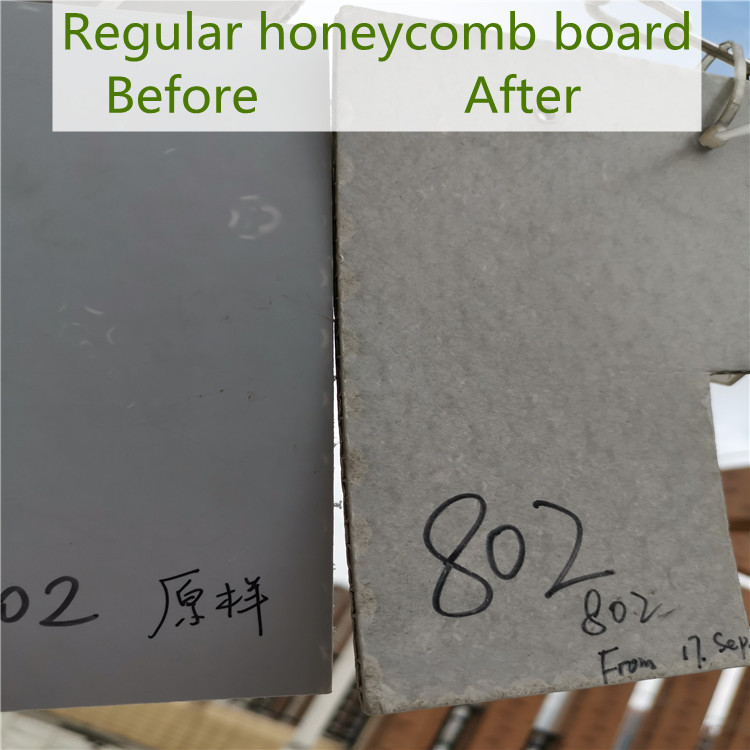

We did a two-years outdoor test on regular honeycomb panels and anti-ultraviolet honeycomb panels.

As for the UV-resistant sample, it has not changed much after two years of testing. However, the test results of ordinary samples are not so good.

Therefore, to slow down the aging speed of PP hollow sheet, the production formula can be adjusted according to different applications, here are the details how Polyreflex do.

* Adding few UV resistant or antioxidant material in product, can effectively improve the atmospheric aging resistance.

* To maintain the color durability, it is necessary to add weather-resistant pigments to adjust the color of the color palette, such as iron oxide red, phthalocyanine blue, carbon black, phthalocyanine green, and titanium dioxide pigments, can improve its weather resistance.

* Adding appropriate amount of titanium dioxide in PP hollow sheet, not only it will not affect the original properties of the sheet, but also it can improve the atmospheric aging resistance of PP hollow sheet.

* Adding appropriate antimony stabilizer to replace lead salt stabilizer in PP hollow sheet, it can improve the impact toughness and atmospheric aging resistance.

For Polyreflex lightweight plastic sheets, different product has different life spans:

1. PP corrugated sheet can be used outdoors for 2 years.

2. PP honeycomb panel and X type twin wall hollow sheet, standard products can be used outdoors for 3 years.

If the service life of 2~3 years is not enough for your application, it can be adjusted by adding high-quality UV resistance enhancer for a service life that more than 5 years.

Welcome to contact us for more information.