When it comes to selecting the right plastic sheet material for your project, it's essential to consider various factors such as performance, versatility, and durability. In this comprehensive comparison, we will delve into the world of plastic sheets, specifically ABS sheets, PVC sheets, and PC sheets. We'll explore their features, benefits, and applications, helping you make an informed decision for your specific needs.

ABS Sheets, PVC Sheets, PC Sheets, What Are They?

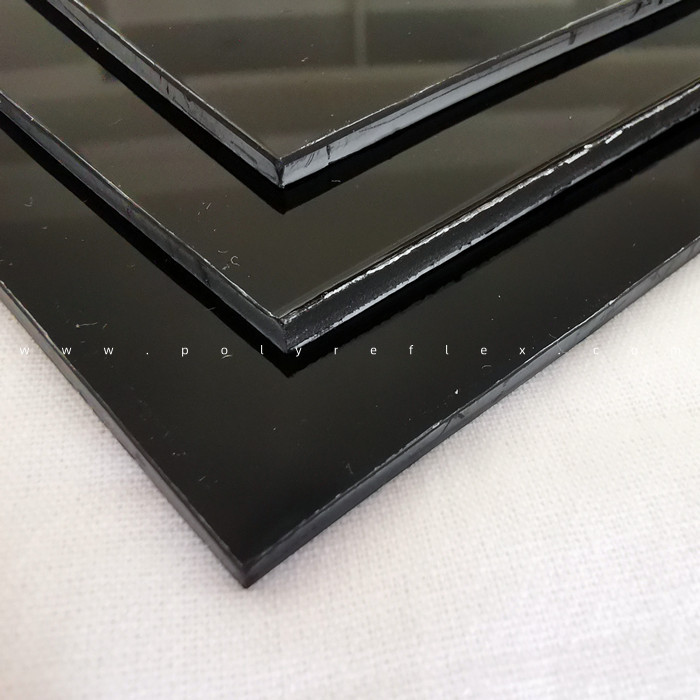

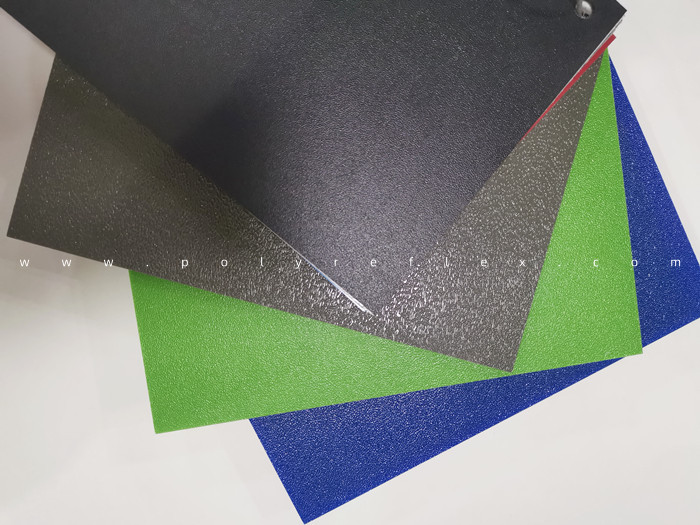

ABS (Acrylonitrile Butadiene Styrene) sheets are a versatile thermoplastic material known for its excellent impact resistance, strength, and aesthetic appeal. ABS sheets are composed of a blend of three monomers, offering a balanced combination of properties. These sheets are available in various thicknesses, sizes, and colors, making them suitable for a wide range of applications.

PVC (Polyvinyl Chloride) sheets are durable and lightweight, known for their excellent chemical resistance and electrical insulation properties. PVC sheets offer good weatherability and are available in different formulations, including rigid and flexible options. They are commonly used in construction, signage, and fabrication applications.

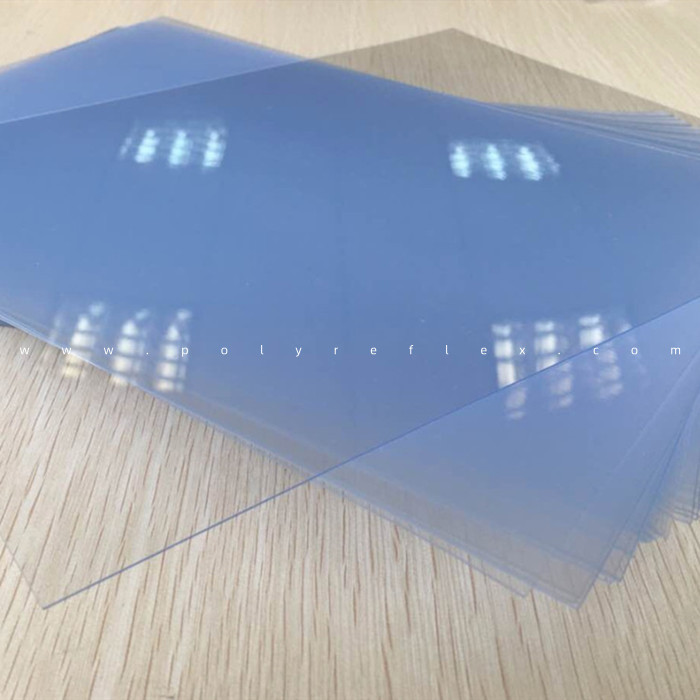

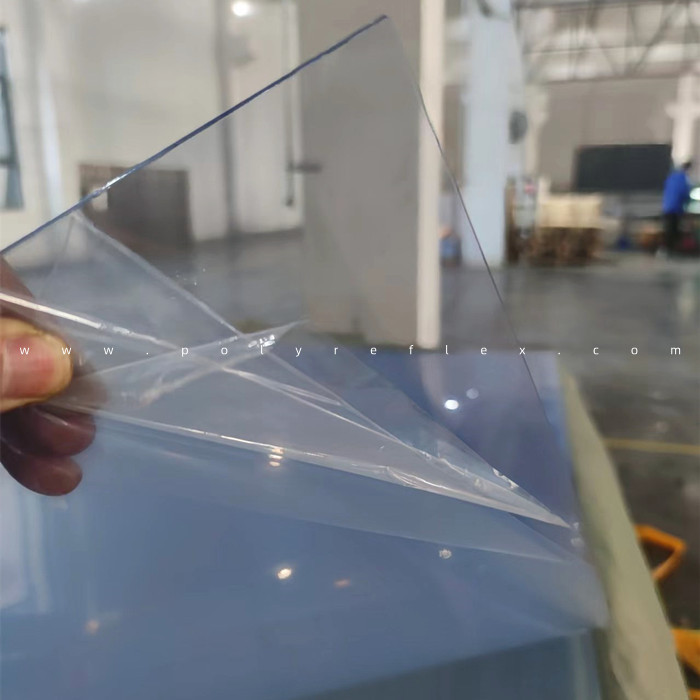

PC (Polycarbonate) sheets are highly transparent and possess exceptional impact strength, making them suitable for applications requiring high clarity and toughness. PC sheets also offer excellent heat resistance and dimensional stability. These sheets find extensive use in industries such as automotive, electronics, and safety equipment.

ABS Sheets, PVC Sheets, PC Sheets, What Are the Differences in Their Performance?

ABS sheets: ABS sheets exhibit excellent impact resistance, making them suitable for applications that require toughness and durability.

PVC sheets: PVC sheets offer moderate impact resistance but may not be as robust as ABS sheets in demanding environments.PC sheets: PC sheets provide superior impact resistance, surpassing both ABS and PVC sheets, making them ideal for applications that require high strength and safety.

ABS sheets: ABS sheets offer good resistance to a wide range of chemicals, including acids and alkalis.

PVC sheets: PVC sheets exhibit excellent chemical resistance, making them suitable for applications exposed to corrosive environments.PC sheets: PC sheets provide moderate chemical resistance, but some chemicals may cause stress cracking.

ABS sheets: ABS sheets have a moderate temperature resistance, typically ranging from -20°C to 80°C (-4°F to 176°F).

PVC sheets: PVC sheets have a limited temperature range, usually between -10°C to 60°C (14°F to 140°F).PC sheets: PC sheets have an excellent temperature resistance, typically ranging from -40°C to 120°C (-40°F to 248°F).

ABS sheets: ABS sheets offer a wide range of color options and can be easily painted or printed on, allowing for greater design flexibility.

PVC sheets: PVC sheets are available in various colors and finishes, including glossy and matte surfaces.PC sheets: PC sheets provide exceptional transparency and optical clarity, making them suitable for applications that require see-through properties.

ABS Sheets, PVC Sheets, PC Sheets, What Are Their Main Application?

ABS Sheets

- Automotive interior parts, such as dashboards, door panels, and trims.

- Electronic enclosures, including computer cases and appliance covers.

- Point-of-purchase displays and signage.

- Protective cases and packaging materials.

- Consumer goods and toys.

PVC Sheets

- Construction applications, such as wall cladding, roofing, and window profiles.

- Electrical insulation and cable management.

- Signage, banners, and displays.

- Fabrication of tanks, pipes, and fittings.

- Healthcare and hygiene products.

PC Sheets

- Safety and security glazing, such as riot shields and safety goggles.

- Transparent machine guards and protective covers.

- Electronic display screens and touch panels.

- Automotive headlamp lenses and taillights.

- Greenhouses and skylights.

Polyreflex: Your Reliable Manufacturing Partner

Polyreflex, as a leading manufacturer and supplier based in China, offers a wide range of ABS sheets, along with various customization services. Our state-of-the-art facilities enable us to provide CNC cutting, laser engraving, vacuum forming, injection molding, and other tailored solutions to meet your specific requirements. With a commitment to quality and customer satisfaction, Polyreflex is your trusted partner for all your thermoplastic sheet needs.

In the battle of ABS sheets vs. PVC sheets vs. PC sheets, each material has its unique advantages and applications. ABS sheets excel in impact resistance and design versatility, while PVC sheets offer excellent chemical resistance and affordability. PC sheets stand out with exceptional clarity and toughness. By understanding the characteristics and considering your project's requirements, you can make an informed choice. Choose Polyreflex, your reliable manufacturing partner, for high-quality ABS sheets and customized solutions tailored to your needs.

Contact us today to request a quote and claim your FREE sample! Let's bring your ideas to life with our exceptional thermoplastic ABS Sheets!