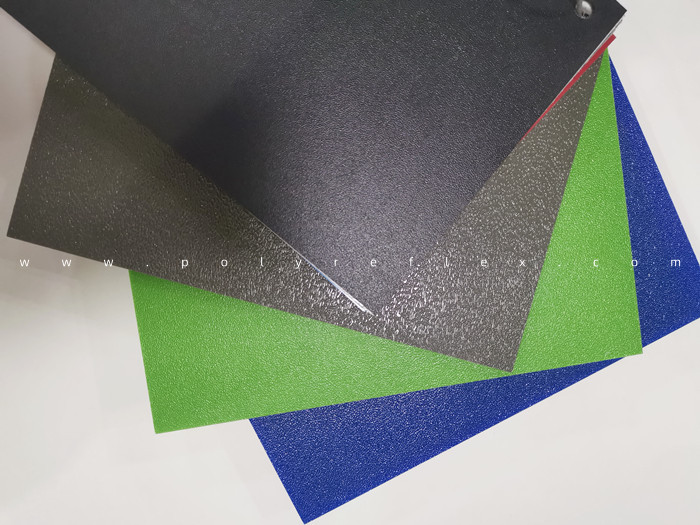

Welcome to Polyreflex, the leading manufacturer of ABS sheets in China. In this article, we will share invaluable knowledge about ABS sheets, showcasing our expertise and guiding you through the world of processing and manufacturing. Discover the endless possibilities that ABS sheets offer and gain practical insights for engineers and manufacturers alike. Let's dive in!

Thermoforming: Shaping Ideas into Reality

ABS sheets possess exceptional heat-forming capabilities, allowing them to be easily molded into desired shapes. Whether you're fabricating complex prototypes, custom enclosures, or intricate components, ABS sheets can be heated and formed using techniques such as thermoforming and vacuum molding. Unlock your creativity and achieve precise designs with the remarkable formability of ABS sheets.

Precision Cutting: Tailoring ABS Sheets to Perfection

Achieving precise dimensions is crucial in many applications, and ABS sheets can be easily cut to meet your exact specifications. Whether you require straight cuts, intricate patterns, or curves, CNC cutting techniques provide unmatched accuracy and consistency. Our state-of-the-art CNC cutting services enable you to create intricate designs with ease, ensuring a perfect fit every time.

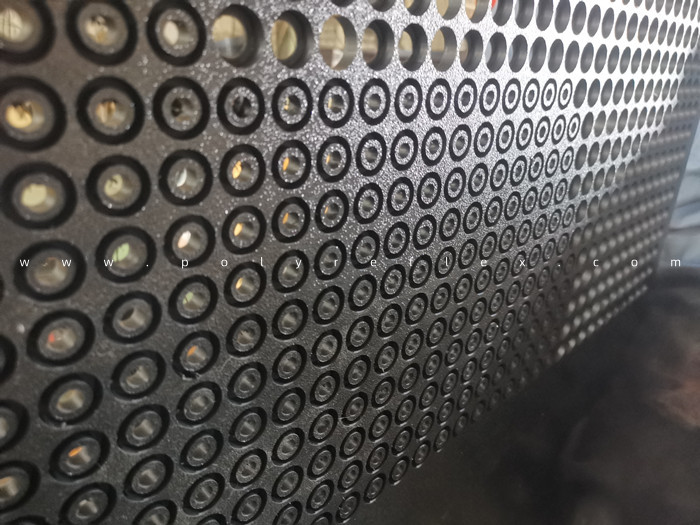

Hole Punching: Seamlessly Integrating Functionality

Integrating functional elements into your ABS sheet projects is a breeze with hole punching techniques. Whether you need holes for fasteners, wiring, or ventilation, ABS sheets offer excellent punchability. Precision hole punching ensures seamless integration and enhances the functionality of your designs. From small perforations to large cutouts, let ABS sheets simplify the assembly process while maintaining structural integrity.

Processing of Perforated ABS Sheets

Surface Treatment: Adding the Finishing Touch

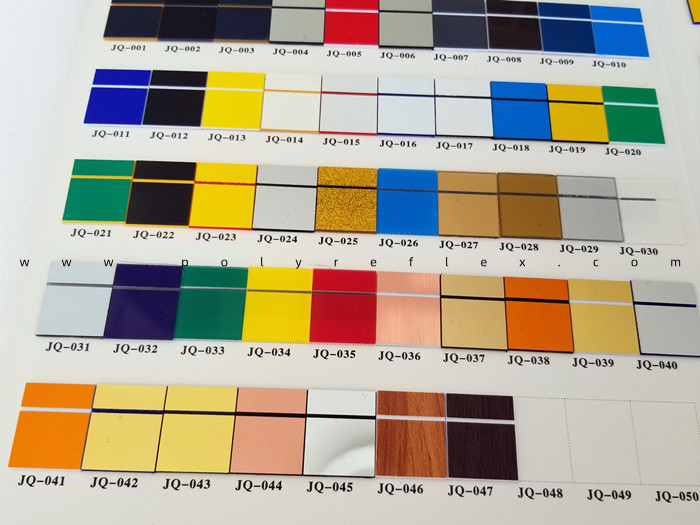

To elevate the visual appeal and durability of your ABS sheet products, consider surface treatments such as printing, painting, and coating. Custom branding, vibrant graphics, or protective finishes can be applied to ABS sheets to enhance their aesthetics and resistance to wear and tear. With our advanced printing and coating capabilities, your ABS sheet creations will leave a lasting impression.

Practical Tips for Working with ABS Sheets

- Ensure proper ventilation and safety measures when heat forming ABS sheets to prevent the release of potentially harmful fumes.

- Optimize CNC cutting parameters to achieve clean and precise cuts, adjusting feed rates and tooling as needed.

- Use sharp, high-quality hole punches and drill bits to maintain clean edges and prevent cracking or chipping.

- Prioritize surface preparation before applying treatments, ensuring the ABS sheets are clean, dry, and free from debris for optimal adhesion and finish.

Polyreflex: Your Trusted ABS Sheets Manufacturer and Customization Expert

At Polyreflex, we go beyond providing high-quality ABS sheets. We offer a range of customization services to meet your specific requirements. Our advanced capabilities include CNC cutting, laser engraving, vacuum forming, and printing, enabling you to add personalized touches to your ABS sheet projects.

ABS sheets from Polyreflex provide a world of possibilities for engineers and manufacturers alike. Discover the versatility of ABS sheets through heat forming, precision cutting, hole punching, and surface treatment techniques. Empower your designs, achieve precision, and enhance functionality with the exceptional capabilities of ABS sheets.

As China's premier manufacturer, Polyreflex is committed to delivering top-quality ABS sheets and providing comprehensive customization services. Contact us today to explore the full potential of ABS sheets and collaborate on your next innovative project. Click here to visit our website and inquire about our services. Unleash your creativity with Polyreflex!

Contact us today to request a quote and claim your FREE sample! Let's bring your ideas to life with our exceptional thermoplastic ABS Sheets!

We look forward to partnering with you on your next venture!