Durability

ABS sheets are renowned for their durability and robustness. They possess excellent resistance to physical impacts, making them highly suitable for applications where materials need to withstand wear and tear. Whether it's for automotive parts, protective casings, or rugged signage, ABS sheets can endure harsh conditions and provide long-lasting performance.

Chemical Stability

One of the standout features of ABS sheets is their resistance to a wide range of chemicals, including acids, alkalis, and various industrial chemicals. This chemical stability makes ABS sheets a preferred choice for applications that involve exposure to potentially corrosive substances, such as laboratory equipment, chemical storage containers, and more.

Impact Resistance

ABS sheets excel in impact resistance, making them ideal for situations where materials need to absorb shock without breaking. This quality is particularly valuable in industries such as automotive manufacturing, where ABS sheets are commonly used for bumpers, interior panels, and dashboard components. Their ability to withstand impacts helps enhance vehicle safety and durability.

Applications of ABS Sheets

ABS sheets find wide-ranging applications across various industries due to their exceptional properties and versatility. Here are some common and noteworthy applications of ABS sheets:

Automotive Components

ABS sheets are extensively used in the automotive industry for manufacturing interior and exterior components. They are employed in the production of dashboard panels, interior trim, door handles, bumpers, and wheel covers. Their durability, impact resistance, and ability to be easily molded into complex shapes make them ideal for enhancing both the aesthetics and safety of vehicles.

Construction and Architecture

In the construction and architectural sectors, ABS sheets serve multiple purposes. They are used for wall cladding, decorative panels, and architectural models. Their ability to offer various surface finishes and textures allows architects and designers to create aesthetically pleasing and functional designs.

Signage

ABS sheets are a popular choice for signage due to their durability and weather resistance. Whether it's outdoor signs, indoor directional signs, or promotional displays, ABS sheets can withstand the elements and maintain their visual appeal over time. They are easily customizable and can be printed with graphics and text for effective communication.

Consumer Products

ABS sheets are extensively used in the production of consumer goods. They are found in items such as toys, luggage, and electronic enclosures. ABS sheets' combination of strength and ease of fabrication makes them suitable for creating a wide range of consumer products that require both durability and aesthetics.

Factors to Consider When Choosing ABS Sheets

Selecting the right ABS sheets for your specific project involves careful consideration of several key factors. To ensure that you make an informed decision, here is a detailed breakdown of the factors to keep in mind:

Dimensions: Start by determining the required size of the ABS sheets. Measure the dimensions needed for your project precisely. Whether you need large sheets for construction or small ones for intricate designs, choose accordingly.Thickness: Consider the thickness of the ABS sheets. Different projects may require different thicknesses for structural stability or flexibility. Make sure to select the appropriate thickness that aligns with your project's requirements.

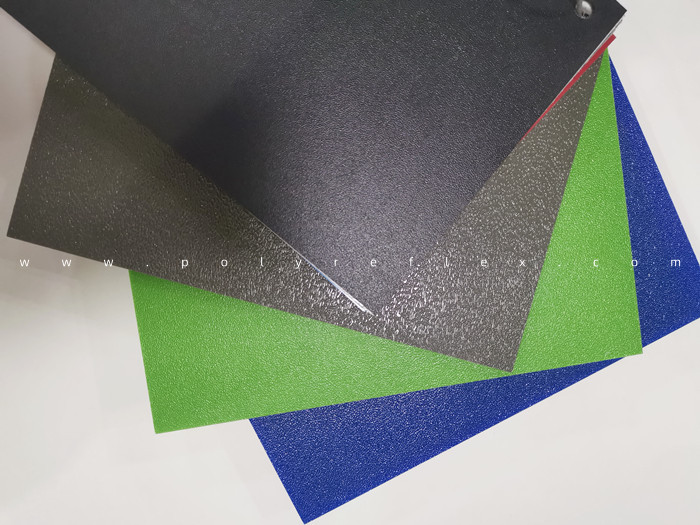

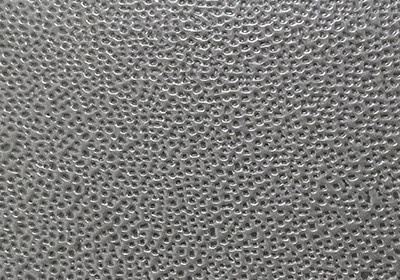

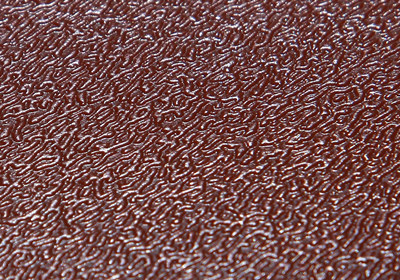

Color Options: ABS sheets come in a wide array of colors. Consider the visual appeal and functionality of your desired color. Some colors may have specific properties, such as UV resistance, which can be important in outdoor applications.Finish: Determine the desired finish for your ABS sheets. Options include smooth, textured, and embossed finishes. Each finish has its unique advantages and can impact the aesthetics and functionality of your project.

Functional Considerations: Think about how the surface texture will affect the performance of your project. For instance, textured surfaces can provide better grip in certain applications, while smooth surfaces may be preferred for aesthetics or ease of cleaning.Aesthetic Appeal: Consider the visual appeal of the surface texture. Depending on your project, the texture may contribute to the overall look and feel. Ensure that the chosen texture aligns with your design vision.

Specific Requirements: Identify any specialized properties your project demands. ABS sheets can be tailored to meet specific needs, such as flame resistance, UV resistance, or compliance with food-grade standards. Discuss these requirements with your supplier to ensure you select the right material.Environmental Conditions: Consider the environmental conditions your ABS sheets will be exposed to. For outdoor applications, UV-resistant ABS sheets are crucial to prevent fading and degradation due to sun exposure.

5. Regulatory Compliance:

Quantity Needed: Determine the quantity of ABS sheets required for your project. Bulk purchases may offer cost advantages, so plan accordingly.Budget Constraints: Discuss your budget with your ABS sheet supplier. They can help you find the right balance between quality and cost to meet your budget constraints without compromising performance.

Factors to Consider When Choosing ABS Sheets

When it comes to purchasing ABS sheets, making an informed decision is essential to ensure the success of your project. Here's a comprehensive purchasing guide to help you navigate the process effectively, with a focus on the services and expertise offered by your company, Polyreflex:

1. Researching Suppliers:

Finding the right supplier is the first step in acquiring high-quality ABS sheets. Here's how you can make an informed choice:

Supplier Reputation: Research suppliers with a solid reputation for delivering top-quality ABS sheets. Look for customer reviews, testimonials, and case studies. Polyreflex, as an industry-leading ABS sheets manufacturer and wholesaler, has a strong track record of providing reliable and durable materials to clients across various industries.Product Range: Assess the range of ABS sheet products offered by potential suppliers. Polyreflex offers a wide selection of ABS sheets in various sizes, thicknesses, colors, and finishes to cater to diverse project needs.

Customization Services: Explore whether the supplier offers customization services. Polyreflex is renowned for its customization capabilities, including laser cutting, CNC engraving, vacuum thermoforming, and injection molding. These services enable you to tailor ABS sheets to your exact specifications.

Ensuring the quality of the ABS sheets is paramount for project success and safety. Here's what to look for:

Certifications: Check if the ABS sheets meet industry standards and certifications for quality and safety. Polyreflex adheres to stringent quality control measures and complies with relevant certifications to guarantee the reliability of its products.Material Samples: Request material samples from potential suppliers, including Polyreflex. Examining samples can help you assess the quality, finish, and suitability of ABS sheets for your project before making a bulk purchase.

3. Budget Considerations:

Balancing your budget while maintaining the desired quality is crucial. Here's how to manage your budget effectively:

Bulk Purchasing: Inquire about bulk purchasing options. Polyreflex offers competitive pricing for bulk orders, allowing you to benefit from cost savings while ensuring a consistent supply of ABS sheets for your projects.Value vs. Cost: Consider the overall value rather than solely focusing on the lowest cost. High-quality ABS sheets, like those offered by Polyreflex, may have a slightly higher initial cost but can lead to long-term cost savings due to their durability and performance.

4. Customization Services by Polyreflex:

Polyreflex stands out as a provider of comprehensive customization services for ABS sheets, which can greatly enhance the versatility and suitability of the materials for your projects:

Laser Cutting: Precision laser cutting enables intricate designs and accurate shapes, making it ideal for applications that require precision and detail.CNC Engraving: Customized engraving services allow you to add logos, branding, or unique designs to your ABS sheets with precision and clarity.

Vacuum Thermoforming: This service enables the creation of 3D shapes and contours in ABS sheets, making them suitable for various applications, from product packaging to automotive components.

Injection Molding: Tailor-made injection-molded ABS parts and components are available, allowing you to meet specific project requirements with precision.

Properly maintaining and caring for ABS sheets is essential to ensure their long-term performance and durability. Follow these key steps:

1. Regular Cleaning: Clean ABS sheets with a mixture of mild soap and water using a soft cloth or sponge. Rinse thoroughly to remove soap residue.2. Avoid Harsh Chemicals: Steer clear of harsh chemicals that can damage ABS sheets. Consult Polyreflex for safe cleaning product recommendations.

3. Temperature Considerations: Protect ABS sheets from extreme temperatures to prevent warping or cracking.

4. Storage: Store ABS sheets in a cool, dry place away from direct sunlight and moisture.

5. Protective Measures: Use edge protectors or appropriate sealing methods to prevent edge damage.

6. Repair and Replacement: Consult Polyreflex for guidance on repairing or replacing damaged ABS sheets.

By following these maintenance and care guidelines, you can ensure the longevity and optimal performance of your ABS sheets from Polyreflex.

Polyreflex: Your Trusted ABS Sheets Manufacturer and Customization Expert

In the vanguard as a preeminent manufacturer and supplier headquartered in China, Polyreflex extends an expansive gamut of ABS sheets, meticulously curated to harmonize with your exacting demands. Our purview transcends the production of conventional ABS sheets. Our offerings encompass bespoke customization services, encompassing precision laser incisions, CNC embellishments, vacuum-induced contouring, and precision injection molding. These provisions empower you to metamorphose ABS sheets in alignment with your project's singular stipulations.