Search This Supplers Products:China manufacturer lightweight plastic corrugated sheets for sign and packaging boxesChina manufacturer good impact strength lightweight pp honeycomb panel for van lining pallet boxChina manufacturer durable plastic pallet container sleeve packs logistics turnover packagingChina manufacturer thermoplastic TPO sheet for automotive floor mats trunk mats truck bed matsChina manufacturer thermoplastic ABS sheet for thermoforming vaccum forming injection moldingChina manufacturer corrosion resistant PP sheet HDPE sheet for chemical industry and aquaculture

Your Trusted ABS Sheets Manufacturer in China: Polyreflex

publisherPolyreflex

time2023/09/12

- Polyreflex - Your trusted ABS sheets manufacturer, specializing in custom, high-quality thermoplastic sheets. Explore our versatile ABS sheets for various applications. ISO 9001 certified quality assurance.

- Raw Material Sourcing: We source raw materials from trusted suppliers, ensuring they meet our stringent quality requirements.

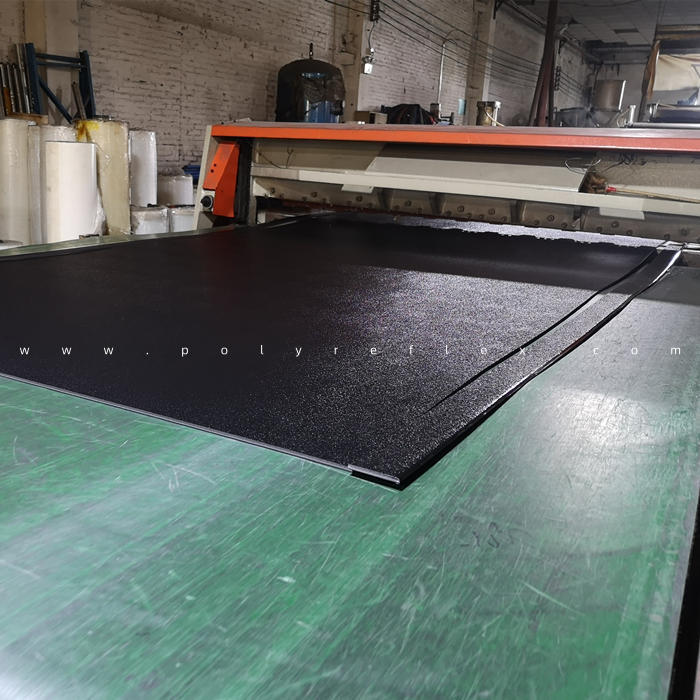

- Precision Manufacturing: Our state-of-the-art manufacturing facilities are equipped with advanced machinery and operated by skilled professionals to guarantee precision in every sheet produced.

- Quality Control Checks: Our quality control team conducts thorough checks at every stage of production, from extrusion to final sizing, to identify and rectify any deviations from specifications.

- ISO 9001:2015 Certification: Polyreflex proudly adheres to the ISO 9001:2015 quality management system, further demonstrating our commitment to quality.

- 1. Stringent Quality Control Checks: Our quality control begins with the selection of raw materials and extends to every stage of production. Each ABS sheet undergoes comprehensive testing to meet or exceed industry standards for properties such as thickness, strength, and color consistency.

- 2. State-of-the-Art Facilities: Our advanced manufacturing facilities are equipped with cutting-edge machinery and operated by skilled professionals. This synergy of technology and expertise ensures precision in every sheet we produce.

- 3. Adherence to Industry Standards: We adhere to globally recognized industry standards and best practices in ABS sheet manufacturing. This commitment guarantees that our products consistently meet the highest benchmarks for quality and performance.

- 4. Customization Control: Even in customized orders, we maintain strict control over the quality of ABS sheets. Tailored products are subject to the same rigorous quality control checks as our standard offerings.

- 5. Quality Feedback Loop: We actively seek feedback from our clients to continuously improve our products and processes. This iterative approach drives innovation and ensures that we remain at the forefront of quality and performance.

- 1. Sheet Thickness: Choose from a range of thickness options to match your project's requirements. Whether you need thin, lightweight sheets or thick, robust ones, we've got you covered.

- 2. Color Selection: ABS sheets are available in a spectrum of colors. Select the color that aligns with your design preferences or branding needs.

- 3. Surface Textures: Customize the surface finish of your ABS sheets. Options include smooth, matte, or textured finishes to achieve the desired look and feel.

- 4. Cut-to-Size: Specify your preferred dimensions, and we'll cut the ABS sheets to precisely fit your application. This minimizes waste and simplifies installation.

- 5. Printing and Branding: If you require logos, labels, or other branding elements on your ABS sheets, we offer printing services to ensure your sheets arrive ready for use.

- Discover Endless Possibilities with Polyreflex ABS Sheets

- Reach Out Now!