Welcome to the world of polyethylene sheets, where choices can sometimes be overwhelming. If you've found yourself wondering about the differences between HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) sheets, you're in the right place. In this comprehensive guide, we'll delve into the unique properties of each material to help you make an informed decision. Whether you're a seasoned professional or a DIY enthusiast, understanding these distinctions is crucial in selecting the right material for your project.

Understanding HDPE Sheets

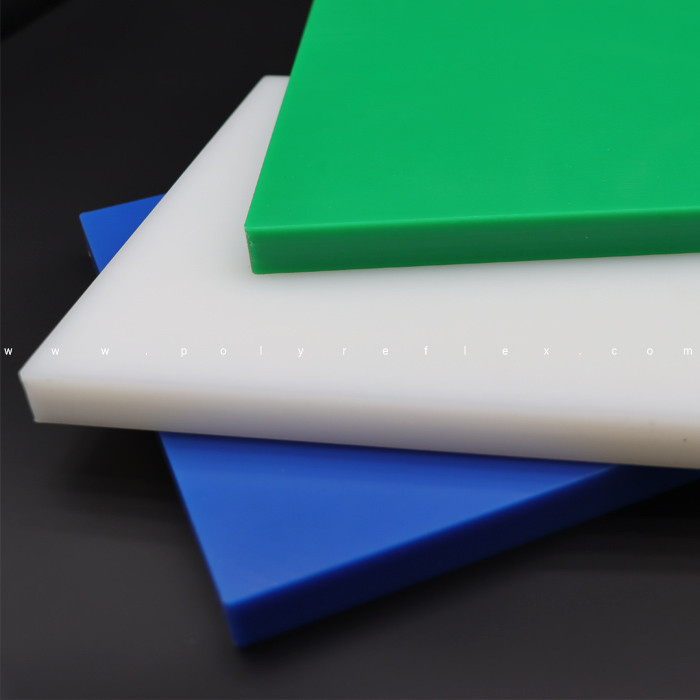

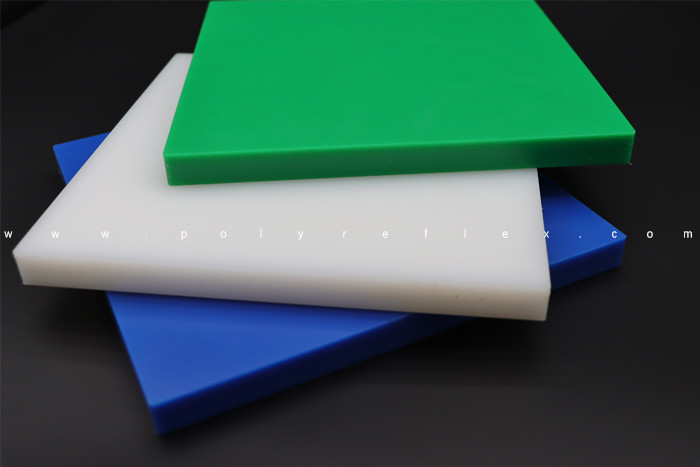

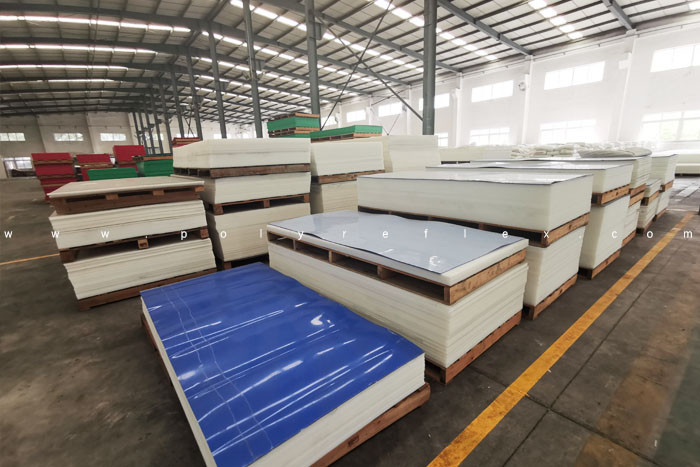

Let's kick off our exploration with HDPE sheets, often touted for their incredible strength and durability. Picture a material that combines flexibility with robustness – that's HDPE in a nutshell. This high-density variant excels in resisting wear and tear, making it an ideal choice for applications requiring long-term structural integrity.

1. Density Matters

HDPE boasts a higher density than LDPE, resulting in a sturdier and more rigid material. This characteristic makes HDPE sheets particularly suitable for projects demanding structural stability, such as:

- Industrial Tanks and Containers: HDPE's robust nature and chemical resistance make it the material of choice for industrial tanks and containers. Whether storing corrosive chemicals or food-grade materials, HDPE ensures the integrity of the stored contents.

- Pipes and Ducts: In the world of plumbing and infrastructure, HDPE pipes shine. Their strength and resistance to corrosion make them ideal for transporting liquids, gases, and even abrasive materials.

2. Chemical Resistance

One of HDPE's standout features is its resistance to a wide range of chemicals. From acids to bases, HDPE sheets are like the superheroes of the polyethylene world, standing strong against corrosive substances. This makes them the go-to option for applications involving chemical exposure, like:

- Chemical Storage Systems: Industries dealing with hazardous materials rely on HDPE for the construction of chemical storage systems. HDPE's resistance ensures the safe containment of chemicals without compromising structural integrity.

3. Weathering the Storm

HDPE doesn't shy away from the elements. UV resistance is a key advantage, making it an excellent choice for outdoor applications, such as:

- Outdoor Furniture: The combination of strength and UV resistance makes HDPE an ideal material for outdoor furniture. From chairs to tables, HDPE ensures that your outdoor space remains stylish and durable.

Understanding LDPE Sheets

Now, let's shift our focus to the counterpart – LDPE sheets. While HDPE leans towards strength and rigidity, LDPE takes a more flexible and malleable approach.

1. Flexibility and Softness

LDPE sheets are characterized by their low density, resulting in a more flexible and pliable material. This flexibility makes LDPE an excellent choice for applications where conformability and ease of handling are paramount, such as:

- Packaging Industry: LDPE's flexibility and ease of processing make it the material of choice for packaging applications. From plastic bags to shrink wrap, LDPE ensures that products are securely packaged while allowing for easy handling.

2. Impact Resistance

LDPE might be softer, but it doesn't compromise on impact resistance. It excels in absorbing shocks and impacts, making it an ideal material for products like:

- Squeeze Bottles and Containers: LDPE's impact resistance makes it perfect for squeeze bottles and containers. It allows for easy dispensing while ensuring the container can withstand the rigors of daily use.

3. Ease of Processing

If you're into DIY projects or manufacturing processes that involve intricate designs, LDPE is your friend. Its low melting point and ease of processing make it a favorite in applications where complex shapes are desired, including:

- Custom Molding and Prototyping: LDPE's malleability makes it an excellent choice for custom molding and prototyping. Whether you're creating prototypes for new products or crafting intricate designs, LDPE allows for creative flexibility.

Choosing the Right Material

Now that we've unraveled the unique properties of HDPE and LDPE sheets, the million-dollar question is, which one is right for you?

1. Consider Your Application

Think about the purpose of your project. If you're constructing a water tank, where chemical resistance and structural stability are crucial, HDPE might be the better choice. On the flip side, if you're working on a packaging project that requires flexibility, LDPE could be the answer.

2. Evaluate Environmental Factors

Assess the environmental conditions your project will face. If it's going to be exposed to harsh sunlight or extreme temperatures, HDPE's UV resistance might tip the scales in its favor.

3. Budget Considerations

While both materials offer unique benefits, budget constraints may play a role in your decision. HDPE tends to be more robust, but LDPE might be the cost-effective solution for projects where extreme strength isn't a primary concern.

In the realm of HDPE and LDPE sheets, the devil is in the details. The choice between these two materials ultimately depends on the specific requirements of your project. Armed with the knowledge of their distinct properties and real-world applications, you can confidently navigate the world of polyethylene and make an informed decision. Whether you're building, packaging, or creating, understanding the nuances of HDPE and LDPE empowers you to choose the perfect material for your needs. Happy crafting!