Welcome to Polyreflex, where we unravel the distinctions between two remarkable materials - HDPE (High-Density Polyethylene) and UHMWPE (Ultra-High-Molecular-Weight Polyethylene). As industry leaders in the manufacturing of polyethylene sheets, we understand the significance of choosing the right material for your specific needs. In this exploration, we delve into the unique characteristics of HDPE and UHMWPE, shedding light on their applications across diverse industries.

HDPE and UHMWPE are both integral players in the world of polymers, finding widespread use due to their exceptional properties. From enhancing structural integrity to minimizing friction, these materials have carved out their niches in various sectors. Whether you're involved in packaging, construction, industrial manufacturing, or seeking solutions for specialized applications, understanding the differences between HDPE and UHMWPE is crucial for making informed decisions.

Join us on this journey as we unravel the distinctive features and applications of HDPE and UHMWPE, empowering you to choose the right material for your projects. Let's navigate the intricacies of these polymers to ensure you make choices that align seamlessly with your unique requirements.

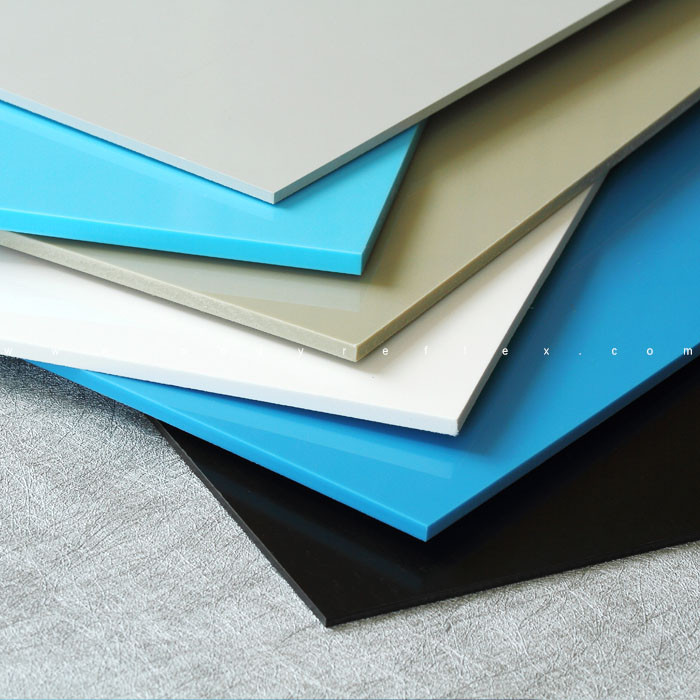

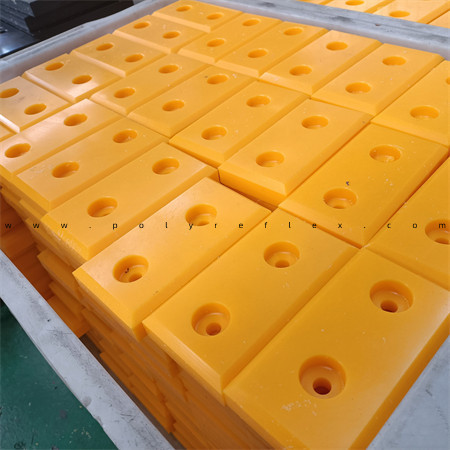

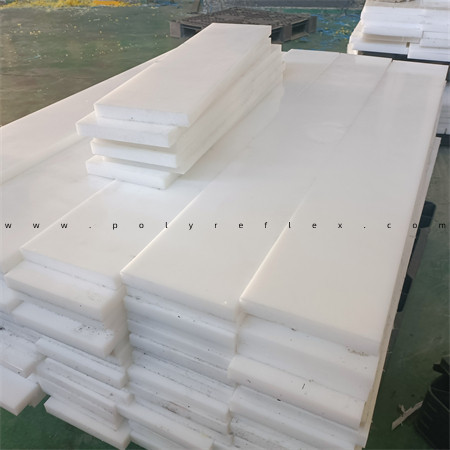

High-Density Polyethylene, commonly known as HDPE, is a versatile and robust thermoplastic with distinctive properties that make it a preferred choice across various industries. Embraced for its high molecular density, HDPE exhibits outstanding strength, durability, and versatility.

In addition to its robustness, HDPE is renowned for its versatility. This thermoplastic material is easily moldable, allowing for various fabrication methods to meet specific project requirements. The combination of strength, chemical resistance, and malleability positions HDPE as a material of choice in diverse sectors.

Applications of HDPE Sheets1. Packaging

HDPE's exceptional strength and resistance make it a staple in the packaging industry. Used widely in food packaging and industrial containers, HDPE sheets ensure the secure transit of products while safeguarding their quality. The material's resistance to impact and chemicals provides an effective barrier against external factors, making it indispensable in the packaging of various goods.

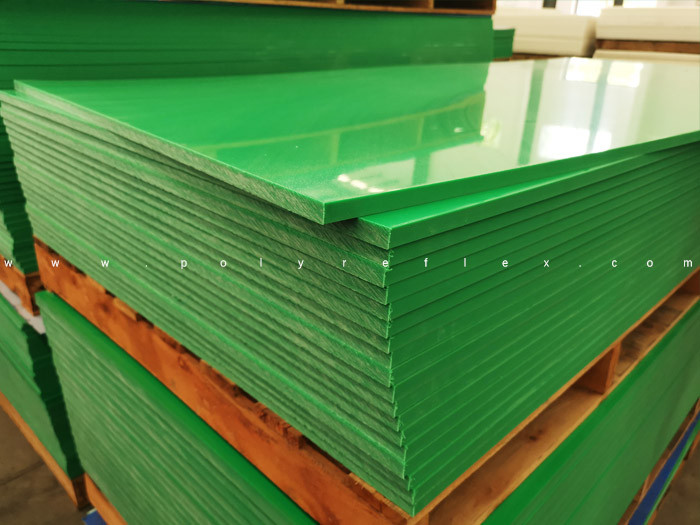

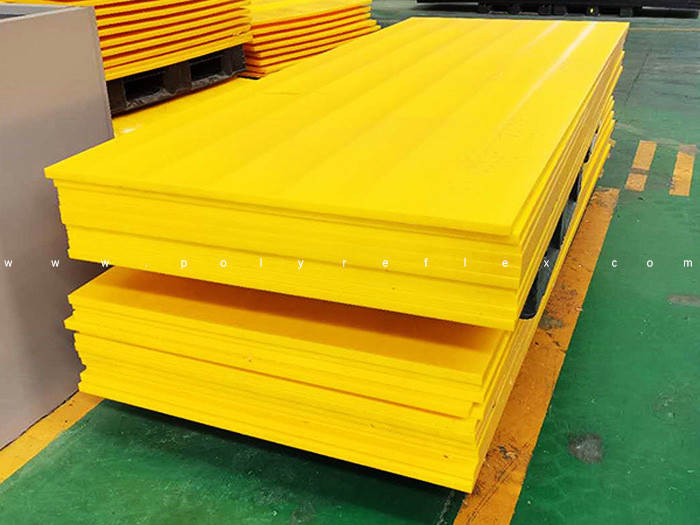

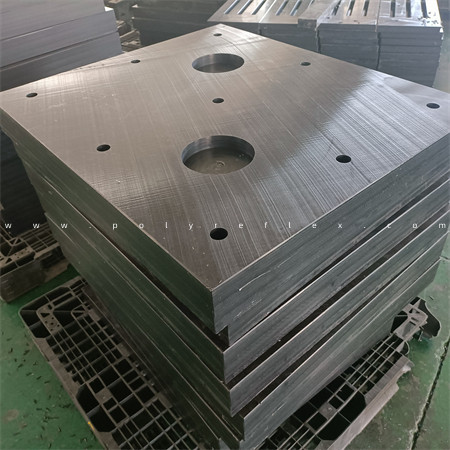

In the construction industry, HDPE sheets find applications in various forms, including geomembranes, pipes, and construction sheets. The high tensile strength of HDPE, combined with its resistance to corrosion, makes it an ideal choice for infrastructure projects. Whether used in water pipes or as a protective lining in construction projects, HDPE contributes to the creation of sustainable and long-lasting structures.

3. Industrial Manufacturing Solutions

HDPE's robust composition makes it a reliable material for fabricating components, machinery parts, and equipment casings in industrial manufacturing. The material's resistance to impact and chemicals ensures the longevity of equipment, even in challenging industrial environments. The flexibility of HDPE allows for precision molding, catering to the intricate specifications often found in manufacturing processes.

In addition to its robustness, HDPE is renowned for its versatility. This thermoplastic material is easily moldable, allowing for various fabrication methods to meet specific project requirements. The combination of strength, chemical resistance, and malleability positions HDPE as a material of choice in diverse sectors.

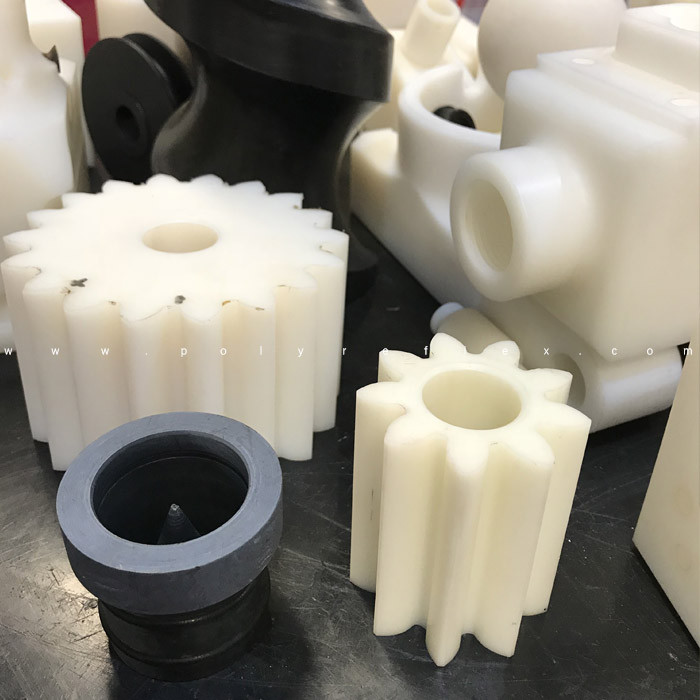

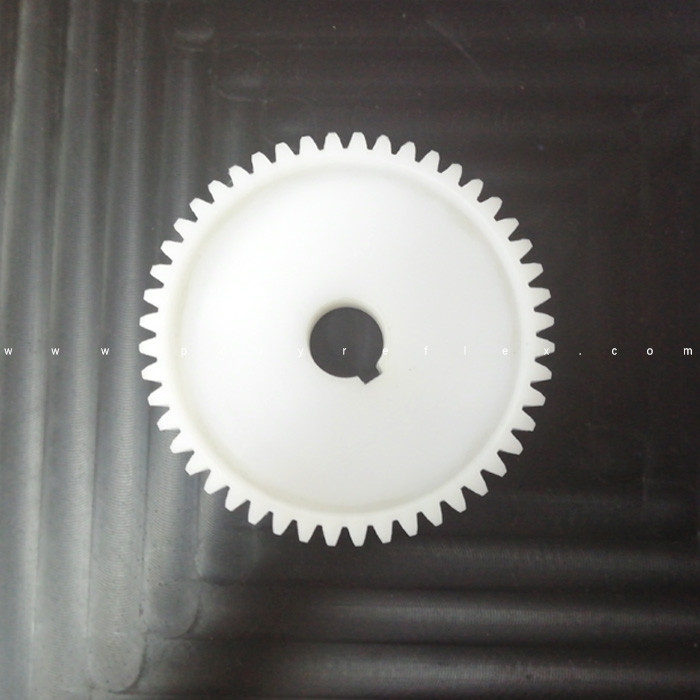

Applications of UHMWPE1. Bearings and Gears

UHMWPE's exceptional abrasion resistance makes it an ideal material for the production of bearings and gears. Its ability to withstand continuous friction without significant wear ensures longevity and reliability in mechanical systems. UHMWPE's low coefficient of friction also contributes to smooth, efficient operation.

UHMWPE's low coefficient of friction and excellent wear resistance find applications in conveyor systems. Components such as rollers, guides, and chutes made from UHMWPE contribute to the smooth and efficient movement of materials along the conveyor, reducing friction and minimizing wear.

3. Specialized Components in Automotive Industry

UHMWPE is utilized in the automotive industry for specialized components where high wear resistance is crucial. It finds applications in various parts, including bushings, gears, and components in the suspension system, contributing to enhanced durability and performance.

The exceptional impact resistance and lightweight nature of UHMWPE make it an excellent choice for sports equipment. Components like ski bases, skateboard wheels, and protective gear benefit from UHMWPE's ability to withstand high impact forces while maintaining durability.

Key Differences Between HDPE and UHMWPE

In the world of polyethylene, the key differences between HDPE (High-Density Polyethylene) and UHMWPE (Ultra-High-Molecular-Weight Polyethylene) lie in their molecular composition, mechanical properties, and the specific applications where each excels.

Simply put, the unique advantages of HDPE and UHMWPE are:

How to Choose the Right Material?

When faced with the decision between HDPE (High-Density Polyethylene) and UHMWPE (Ultra-High-Molecular-Weight Polyethylene), selecting the appropriate material requires careful consideration of the specific project requirements. Each material comes with its unique set of advantages, and understanding the factors that influence material choice is crucial for optimal performance.

1. Load-Bearing Capacity

HDPE: HDPE is renowned for its robustness and high tensile strength. If your project involves load-bearing structures or applications where strength is a primary concern, HDPE may be the ideal choice. It provides reliable support and durability in construction and industrial settings.UHMWPE: While UHMWPE also exhibits impressive strength, its focus lies more on impact resistance and abrasion performance. For load-bearing applications with high wear and tear, UHMWPE can offer exceptional durability and longevity.

2. Wear Resistance

HDPE: HDPE provides good wear resistance, making it suitable for applications where moderate wear is expected. It performs well in scenarios where durability is essential, but extremely high abrasion resistance is not the primary requirement.UHMWPE: UHMWPE shines when it comes to wear resistance. Its ultra-high molecular weight contributes to a low coefficient of friction, reducing wear in applications such as bearings, gears, and conveyor systems. Choose UHMWPE when dealing with environments where abrasion is a critical factor.

3. Chemical Resistance

HDPE: HDPE is known for its excellent resistance to chemicals, making it a reliable choice for applications where exposure to corrosive substances is expected. This makes HDPE sheets suitable for use in packaging, industrial containers, and various chemical-resistant structures.UHMWPE: UHMWPE also exhibits good chemical resistance, although it may not surpass the chemical resistance of HDPE in all cases. Consider UHMWPE for applications where both chemical resistance and superior wear resistance are crucial.

4. Specific Application Considerations

HDPE: Opt for HDPE when versatility and general-purpose use are paramount. Its ability to balance strength, chemical resistance, and malleability makes it suitable for a wide range of applications, including packaging, construction, and industrial manufacturing.UHMWPE: Choose UHMWPE when dealing with high-wear applications, such as in the production of specialized components requiring exceptional abrasion resistance. Its unique properties make it an excellent fit for projects where reducing friction and wear are critical.

As you navigate the diverse applications and properties of HDPE and UHMWPE, we encourage you to make decisions tailored to your unique project requirements. Whether you prioritize the versatility of HDPE or the specialized characteristics of UHMWPE, understanding the specific demands of your application is paramount.

Polyreflex stands as your trusted partner in material solutions. Our commitment to innovation, reliability, and sustainability is reflected in the quality of our HDPE and UHMWPE sheets. Explore the possibilities, weigh the advantages, and let informed decisions guide your material selection.