Welcome to the world of Polyreflex, where innovation meets reliability, and where High-Density Polyethylene (HDPE) sheets take center stage. In the dynamic landscape of various industries, HDPE sheets have emerged as indispensable materials, serving as the backbone for a multitude of applications. From industrial manufacturing to agriculture, aquaculture, and even ensuring playground safety, the versatility of HDPE is unparalleled.

HDPE sheets, known for their unique composition and exceptional mechanical properties, have become the cornerstone of success across diverse sectors. Their significance resonates in the robustness they bring to constructions, the sustainability they contribute to agriculture, the reliability they offer in aquaculture, and the safety they ensure in playgrounds.

As we embark on this exploration, the central question comes to the forefront: What attributes make HDPE sheets the ideal choice for various industries? Join us as we delve into the distinct qualities and applications that position HDPE sheets as a versatile and reliable solution, addressing the needs of different sectors and contributing to advancements across the board. Let's unravel the layers of innovation woven into every HDPE sheet, making it the go-to material for a wide array of industrial applications.

Section 1: Understanding HDPE Sheets

High-Density Polyethylene, commonly known as HDPE, is a thermoplastic polymer renowned for its high strength-to-density ratio. It is derived from ethylene, a gas produced during the refining of natural gas or crude oil. HDPE is characterized by a high level of crystallinity, resulting in a dense and sturdy structure that imparts remarkable mechanical properties.

Manufacturing Process

The manufacturing of HDPE sheets involves a series of intricate steps, starting with the polymerization of ethylene under controlled conditions. This process creates long chains of polyethylene molecules. The polymer chains are then extruded through a die to form a continuous sheet, which is later cooled and cut into specific dimensions. The sheets can undergo additional processing steps, such as annealing or surface treatments, to enhance their properties for specific applications.

Unique Properties of HDPE

1. High Tensile Strength: HDPE sheets boast exceptional strength, making them resistant to deformation under heavy loads. This property ensures their reliability in applications requiring structural integrity.

2. Chemical Resistance: HDPE exhibits remarkable resistance to a wide range of chemicals, acids, and bases. This chemical inertness makes it an ideal choice for applications where exposure to corrosive substances is a concern.

3. Flexibility and Durability: HDPE strikes a perfect balance between flexibility and durability. This enables easy fabrication and molding into various shapes while ensuring the longevity of the material in diverse environments.

4. Weather Resistance: HDPE sheets are highly resistant to UV radiation and extreme weather conditions, making them suitable for outdoor applications. This weather resistance contributes to their durability and performance over time.

5. Impermeability: HDPE is impermeable to liquids and gases, serving as an effective barrier. This property is particularly valuable in applications like packaging and agriculture, where preventing the penetration of external elements is crucial.

6. Recyclability: One of the environmentally friendly aspects of HDPE is its recyclability. HDPE sheets can be recycled and reused in different forms, aligning with sustainable practices and reducing the environmental impact of plastic waste.

Understanding these unique properties lays the foundation for comprehending why HDPE sheets are highly sought after across a spectrum of industries. As we navigate through the subsequent sections, we will explore how these properties translate into real-world applications, making HDPE the preferred choice for various industrial needs.

Section 2: The Versatility of HDPE in Industrial Manufacturing

The versatility of HDPE sheets finds its pinnacle in the realm of industrial manufacturing. Their unique combination of strength, flexibility, and chemical resistance makes them a preferred material for a diverse range of applications within this sector.

Manufacturing Components

HDPE sheets play a crucial role in the creation of various industrial components. The material's high tensile strength ensures that components remain robust under demanding conditions. From intricate machinery parts to structural elements, HDPE contributes to the efficiency and reliability of industrial processes.

Machinery Parts and Equipment Casings

In the manufacturing landscape, where precision is paramount, HDPE sheets excel in the fabrication of machinery parts and equipment casings. The flexibility of HDPE allows for intricate molding, ensuring that parts meet specific design requirements. Whether as protective casings or internal components, HDPE's durability and resistance to chemical exposure contribute to the longevity of machinery and equipment.

Section 3: Aquaculture Advancements with HDPE

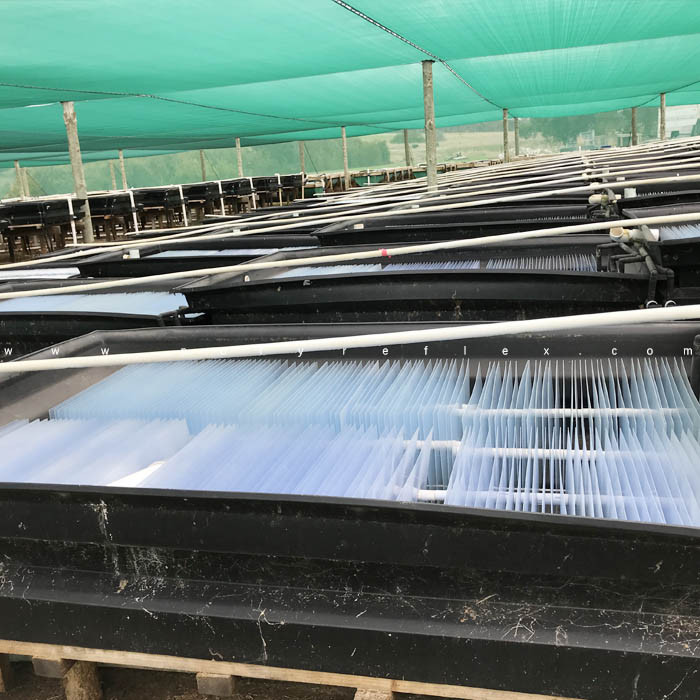

Introduction to HDPE in Aquaculture

Aquaculture, the practice of cultivating aquatic organisms, has experienced significant advancements with the integration of HDPE materials. HDPE's unique combination of durability, chemical resistance, and low maintenance requirements has positioned it as a cornerstone in the development of sustainable and efficient aquaculture systems.

Constructing Fish Tanks

HDPE plays a crucial role in the construction of fish tanks, providing a reliable and durable containment solution. The durability of HDPE ensures that fish tanks withstand environmental stresses, including fluctuating water conditions and varying temperatures. The chemical resistance of HDPE is particularly valuable in aquaculture, where exposure to salts, minerals, and other waterborne substances is common. This resistance safeguards the structural integrity of fish tanks, promoting a healthy and secure environment for aquatic life.

Floating Cages and Infrastructure

HDPE's versatility extends to the creation of floating cages and other aquaculture infrastructure. Floating cages, used for fish farming in open water, benefit from HDPE's buoyancy and resistance to corrosion. HDPE's low maintenance requirements make it an ideal choice for structures exposed to aquatic environments. Whether used for fish farming or other aquaculture activities, HDPE infrastructure ensures long-term stability and performance.

Durability in Harsh Aquatic Environments

1. Resistance to Corrosion: HDPE's resistance to corrosion is pivotal in aquaculture, where exposure to saltwater and other corrosive elements is constant. This resistance ensures the longevity of fish tanks and infrastructure, reducing the need for frequent replacements.

2. Buoyancy for Floating Cages: The buoyant nature of HDPE makes it well-suited for constructing floating cages. These cages provide a controlled environment for fish farming in open water, and HDPE's buoyancy contributes to the stability and functionality of these structures.

3. Low Maintenance Requirements: HDPE's low maintenance needs are especially advantageous in aquaculture settings, where regular upkeep can be challenging. The material's resilience minimizes the effort and resources required for ongoing maintenance, making it a cost-effective choice for aquaculture operations.

Section 4: Playground Safety and HDPE

Ensuring Safe Play Environments

The safety of children is of paramount importance in playground design, and HDPE sheets emerge as a pivotal material in creating secure and enjoyable play environments. This section delves into the significance of HDPE sheets in promoting playground safety, exploring their unique qualities that make them an ideal choice for play equipment.

Impact Resistance for Child Safety

HDPE's exceptional impact resistance is a game-changer in the context of playgrounds. Play equipment crafted from HDPE sheets absorbs and disperses impact forces, reducing the risk of injuries during play. Whether it's swings, slides, or climbing structures, the robust nature of HDPE ensures that the equipment can withstand the rigors of enthusiastic play while prioritizing the safety of children.

Non-Toxic Nature of HDPE

HDPE's non-toxic nature adds an extra layer of safety to play environments. Children often come into direct contact with play equipment, and the use of non-toxic materials, such as HDPE, ensures that their play experience is not only fun but also safe. Parents and caregivers can have peace of mind, knowing that the materials in the playground are free from harmful substances, promoting the overall well-being of children.

HDPE's role in enhancing playground safety goes beyond the physical attributes of impact resistance and non-toxicity. It provides a sense of assurance to parents and caregivers, knowing that the materials chosen for play equipment prioritize the well-being and safety of their children.

In the expansive realm of industrial materials, High-Density Polyethylene (HDPE) stands out as a versatile and transformative solution across various sectors. As we've journeyed through the diverse applications of HDPE sheets, it's evident that these materials are more than just a choice; they are a testament to innovation, reliability, and environmental consciousness.

By choosing Polyreflex, you're not merely selecting a product; you're investing in a partnership that prioritizes durability, versatility, and sustainability. Explore the possibilities with HDPE and let Polyreflex be your trusted companion in material solutions.