In today's ever-evolving industrial landscape, the choice of materials plays a pivotal role in shaping the performance, functionality, and sustainability of products across various sectors. As such, understanding the characteristics and applications of different materials is paramount for manufacturers, designers, and consumers alike.

Introduction to ABS Plastic Sheets

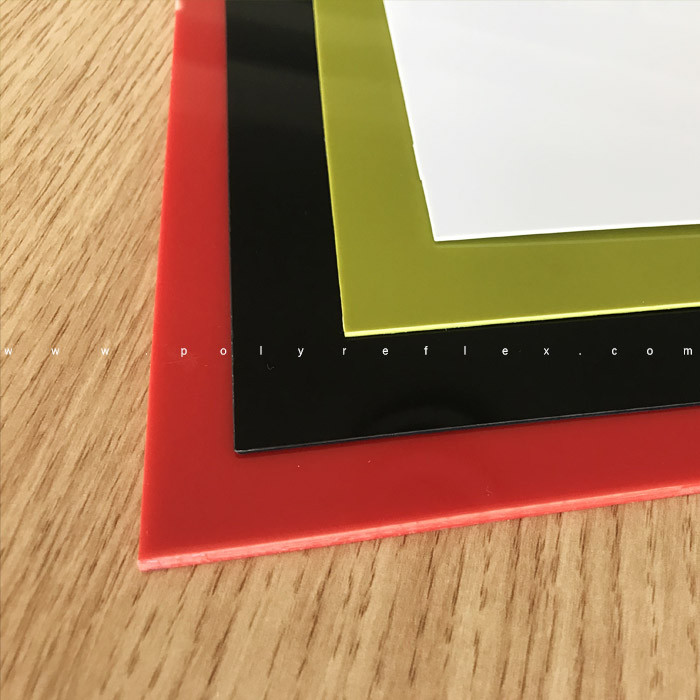

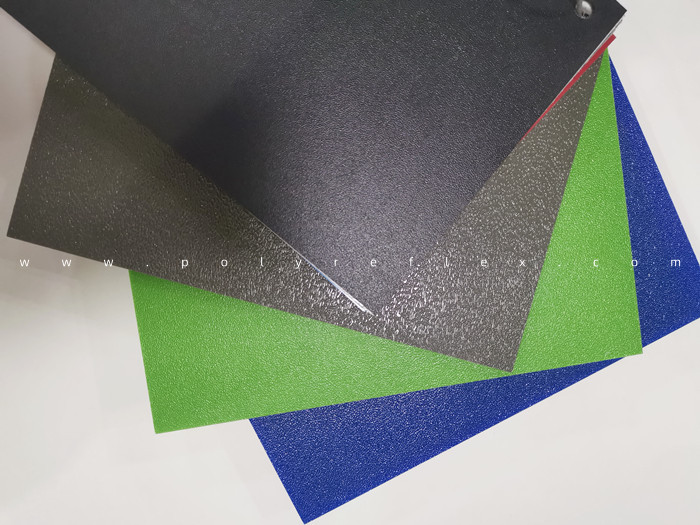

ABS plastic sheets represent a cornerstone of modern material innovation, boasting a unique blend of acrylonitrile, butadiene, and styrene polymers. This amalgamation yields a thermoplastic renowned for its exceptional versatility and resilience. Acrylonitrile contributes to ABS's strength and chemical resistance, while butadiene enhances its impact resistance and toughness. Styrene imparts rigidity and ease of processing, resulting in a material that combines strength with flexibility.

In essence, ABS plastic sheets are engineered to excel in a multitude of applications across diverse industries. Whether in automotive manufacturing, electronics, construction, or consumer goods, ABS sheets offer a reliable solution characterized by durability and adaptability. From intricate electronic casings to robust automotive components, ABS plastic sheets stand as a testament to innovation and functionality.

Applications of ABS Plastic Sheets

ABS plastic sheets find widespread usage across various industries due to their versatile properties and durability. Let's delve into some of the key applications where ABS sheets shine:

1. Automotive Industry:

ABS plastic sheets play a crucial role in the automotive sector, where they are utilized for manufacturing dashboard components, trim panels, and interior fittings. Their lightweight nature, coupled with excellent impact resistance, makes them ideal for withstanding the rigors of automotive environments. Additionally, ABS sheets can be easily molded into intricate shapes, allowing for the creation of aesthetically pleasing and functional automotive components.

2. Electronics:

In the electronics industry, ABS plastic sheets serve as protective housings for various appliances and devices, including computer casings, televisions, and home entertainment systems. ABS's ability to withstand temperature fluctuations and provide electrical insulation makes it a preferred material for electronic enclosures. Furthermore, ABS sheets offer excellent surface finish options, enhancing the visual appeal of electronic products.

3. Construction:

ABS plastic sheets are widely employed in the construction sector for fabricating pipes, fittings, and protective coverings. Their corrosion resistance, coupled with high impact strength, makes them suitable for use in plumbing systems and building structures. ABS sheets are also favored for their ease of installation and low maintenance requirements, contributing to cost-effective construction solutions.

4. Consumer Goods:

ABS plastic sheets are a staple in the production of various consumer goods, including luggage, toys, and sporting equipment. Their lightweight yet durable nature makes them ideal for applications where impact resistance and aesthetics are paramount. ABS sheets can be easily molded into different shapes and colors, offering designers and manufacturers endless possibilities for creating innovative and appealing consumer products.

In summary, ABS plastic sheets offer a versatile and reliable solution for a wide range of applications across industries. Whether in automotive manufacturing, electronics, construction, or consumer goods, ABS sheets deliver durability, functionality, and aesthetic appeal, making them indispensable in modern manufacturing processes.

Advantages of ABS Plastic Sheets

ABS plastic sheets offer a myriad of advantages that make them a preferred choice for various applications. Let's explore these advantages in detail:

1. Impact Resistance

One of the standout features of ABS plastic sheets is their exceptional impact resistance. ABS can withstand significant forces without cracking or breaking, making it ideal for applications where durability is paramount. Whether it's in automotive components, electronics housings, or consumer goods, ABS sheets provide reliable protection against impacts and mechanical stresses.

2. Durability

ABS plastic sheets are renowned for their durability and longevity. Unlike some other materials that may degrade over time, ABS maintains its structural integrity even in demanding environments. This durability ensures that products made from ABS sheets have a longer service life, reducing the need for frequent replacements and maintenance.

3. Easy to Fabricate and Machine

Another key advantage of ABS plastic sheets is their ease of fabrication and machining. ABS can be easily cut, drilled, and shaped using common tools and techniques, allowing for precise customization and assembly. This versatility in fabrication makes ABS sheets highly adaptable to various design requirements, enabling manufacturers to create complex and intricate components with ease.

4. Heat and Chemical Resistance

ABS plastic sheets exhibit excellent resistance to heat and chemicals, further enhancing their suitability for a wide range of applications. ABS can withstand moderate temperatures without deforming or losing its mechanical properties, making it suitable for both indoor and outdoor use. Additionally, ABS resists degradation when exposed to common chemicals, ensuring the integrity of products in chemical-rich environments.

In summary, ABS plastic sheets offer a compelling combination of impact resistance, durability, ease of fabrication, and heat/chemical resistance. These advantages make ABS sheets a versatile and reliable material choice for diverse applications across industries, from automotive and electronics to construction and consumer goods.

Environmental Considerations

1. Recyclability of ABS Plastic Sheets: ABS plastic sheets offer environmental benefits through their recyclability. Recycling ABS material helps reduce waste and conserves resources by diverting plastic from landfills. Polyreflex is committed to promoting sustainability by offering ABS sheets that are recyclable at the end of their lifecycle. By incorporating recycled ABS into new products, we contribute to a circular economy and minimize the environmental footprint of our manufacturing processes.

2. Sustainable Manufacturing Practices: At Polyreflex, we prioritize sustainable manufacturing practices to minimize our environmental impact. We adhere to stringent environmental standards throughout the production process, from sourcing raw materials to waste management. Our facilities are equipped with energy-efficient technologies, and we strive to reduce water consumption and emissions. By embracing sustainable practices, we aim to mitigate environmental harm while delivering high-quality ABS plastic sheets to our customers.

In conclusion, ABS plastic sheets stand as a testament to versatility, durability, and innovation in the realm of materials engineering. From automotive components to electronics housings, construction applications to consumer goods, ABS sheets offer a reliable solution for a wide range of industries and projects. Their impact resistance, ease of fabrication, and heat/chemical resistance make them indispensable in modern manufacturing processes.

Polyreflex is dedicated to providing top-quality ABS plastic sheets tailored to meet the diverse needs of our customers. We invite you to explore our extensive range of ABS sheets and unlock the potential of this versatile material for your next project. With Polyreflex, you're not just getting a product; you're gaining a partner committed to delivering excellence and sustainability in every aspect of our operations. Discover the possibilities with ABS sheets from Polyreflex and elevate your projects to new heights of success.