1. Overview of PP Honeycomb Panels

What are PP Honeycomb Panels?

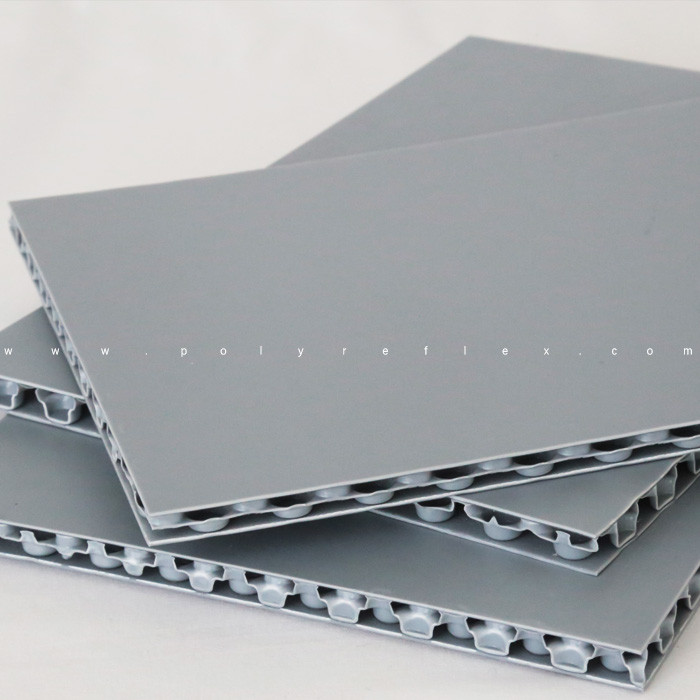

PP Honeycomb Panels are innovative materials constructed from a core of polypropylene (PP) honeycomb structure sandwiched between two layers of rigid PP sheets. This unique design combines the best of both worlds: the lightweight, shock-absorbing core provides structural integrity, while the outer layers offer durability and resistance to impact. The result is a panel that excels in both strength and efficiency, making it a preferred choice across various industries.

Lightweight: One of the standout features of PP Honeycomb Panels is their remarkably low weight. The honeycomb core structure significantly reduces the panel's overall mass without compromising strength. This makes handling and transportation more manageable and cost-effective.Strong and Durable: Despite their lightness, these panels are incredibly strong and durable. The honeycomb core enhances load-bearing capacity and resistance to bending, making them ideal for applications where strength is crucial.Eco-Friendly: PP Honeycomb Panels are made from polypropylene, which is recyclable and environmentally friendly. This sustainable approach aligns with modern environmental standards and helps reduce waste in various applications.

Packaging: In the packaging industry, PP Honeycomb Panels are utilized for creating robust, lightweight, and protective packaging solutions. Their strength ensures that products are well-protected during transit, while their low weight reduces shipping costs.Construction: These panels are increasingly used in construction for applications like wall partitions, ceilings, and flooring. Their strength and durability make them suitable for structural elements, while their light weight simplifies installation.Automotive: In the automotive sector, PP Honeycomb Panels are employed in manufacturing interior components and structural parts. Their impact resistance and low weight contribute to improved vehicle performance and safety.

In summary, PP Honeycomb Panels offer a blend of lightweight efficiency, durability, and environmental benefits, making them a versatile choice for a range of applications across different industries.

Customization and Versatility

When it comes to customization and versatility, PP Honeycomb Panels offer a high degree of flexibility. They can be easily molded into various shapes and sizes to meet specific design requirements, making them suitable for a wide range of applications. Traditional materials like plywood and MDF can also be customized, but their processing can be more labor-intensive and less adaptable to complex designs. Aluminum offers customization in terms of strength and aesthetics but at a higher cost and with less flexibility in design compared to the adaptable nature of PP Honeycomb Panels.

3. Applications and Use Cases

4. Customer Testimonials and Case Studies

By choosing PP Honeycomb Panels, you're investing in a material that not only meets but exceeds the demands of modern industries. Their innovative design and practical advantages make them a standout option for enhancing efficiency and reducing costs.