1. What Are PP Honeycomb Panels?

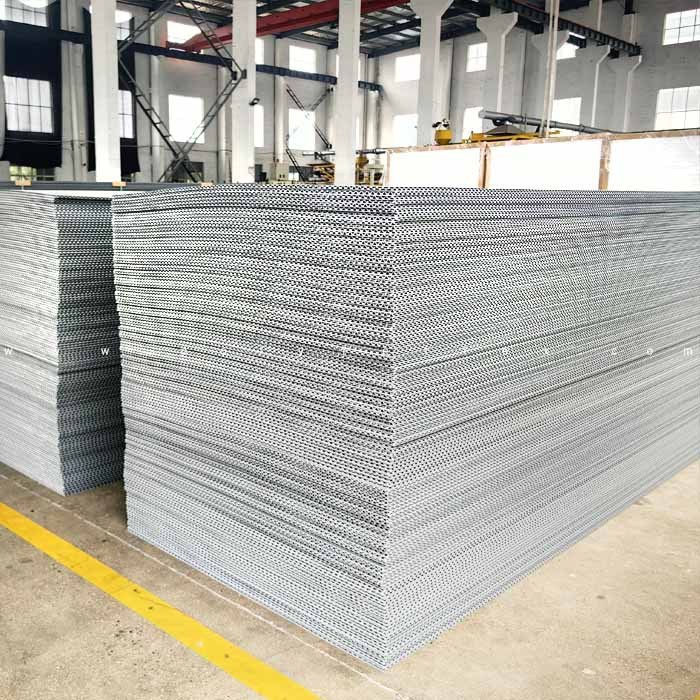

PP Honeycomb Panels are advanced materials designed for a range of industrial and commercial applications. Constructed from polypropylene, these panels feature a unique honeycomb structure sandwiched between two flat skins. This innovative design results in a lightweight yet incredibly strong material, ideal for various uses.

Definition and Construction

PP Honeycomb Panels consist of a honeycomb core made from polypropylene, which is encased in two outer layers of the same material. The honeycomb structure, resembling the geometric cells of a beehive, provides exceptional strength and rigidity while maintaining a low weight. This design not only enhances the panel's structural integrity but also contributes to its superior impact resistance and thermal insulation properties.

Lightweight: The honeycomb core reduces the overall weight of the panel, making it easier to handle and install. This lightweight nature also translates to lower transportation costs and reduced structural load.Durable: Despite its lightweight composition, PP Honeycomb Panels offer impressive durability. They are resistant to impacts, scratches, and general wear and tear, ensuring a long service life in demanding environments.Eco-Friendly: Made from recyclable polypropylene, these panels are an environmentally responsible choice. Their production process generates minimal waste, and the material itself can be recycled at the end of its life cycle.

Comparison with Other Panel Types

When compared to other types of panels, such as MDF or traditional plastic sheets, PP Honeycomb Panels stand out due to their superior strength-to-weight ratio. Unlike MDF, which is denser and more prone to moisture absorption, PP Honeycomb Panels offer greater resistance to environmental factors and are not susceptible to warping or swelling. In comparison to solid plastic sheets, the honeycomb structure provides a more efficient use of material, reducing weight while maintaining strength. Overall, PP Honeycomb Panels provide a compelling combination of performance, cost-effectiveness, and environmental benefits.

2. Initial Costs vs. Long-Term Savings

When evaluating the cost-effectiveness of PP Honeycomb Panels, it's essential to balance initial investment against long-term savings. Here's a closer look at how these panels perform in both short-term and long-term cost scenarios.

Competitive Initial Pricing

The initial costs of PP Honeycomb Panels include both the material and installation expenses. Typically, the material cost for PP Honeycomb Panels is competitive compared to other high-performance materials. Their lightweight nature not only reduces the cost per square meter but also lowers transportation expenses. Installation costs are generally lower as well, due to the ease of handling and cutting these panels. The straightforward installation process can minimize labor costs and shorten project timelines, adding to their cost-effectiveness.

Analysis of Long-Term Savings

The true cost-effectiveness of PP Honeycomb Panels becomes evident over time, thanks to their durability and low maintenance requirements. Here's how:

Durability: The robust construction of PP Honeycomb Panels ensures they withstand impacts, weather conditions, and general wear and tear. Their resilience means fewer replacements and repairs, translating to significant savings over the panel's lifespan. Unlike materials that may degrade or require frequent replacements, PP Honeycomb Panels provide long-lasting performance.Maintenance Costs: One of the most significant advantages of PP Honeycomb Panels is their minimal maintenance needs. The panels are resistant to stains, corrosion, and moisture, reducing the frequency and cost of upkeep. Regular cleaning is typically all that’s required, saving on both time and money.Longevity: The long service life of PP Honeycomb Panels further contributes to their cost-effectiveness. By avoiding frequent replacements and repairs, users benefit from a lower total cost of ownership. The extended lifespan of these panels ensures that the initial investment continues to pay off, making them a smart choice for long-term projects.

In summary, while the initial costs of PP Honeycomb Panels are competitive, the real savings come from their durability, low maintenance, and long-lasting performance. This combination makes them a cost-effective solution not just in the short term but throughout their extended service life.

3. Durability and Longevity

PP Honeycomb Panels are celebrated for their exceptional durability and longevity, attributes that make them a cost-effective choice for various applications. Let's explore the factors contributing to their impressive lifespan and how they stand up to everyday challenges.

Factors Contributing to Longevity

Robust Core Structure: The honeycomb core design of PP Honeycomb Panels plays a crucial role in their durability. This structure provides excellent strength-to-weight ratio, allowing the panels to absorb and distribute impact forces effectively. As a result, the panels maintain their structural integrity even under significant stress or heavy loads.High-Quality Polypropylene: Made from high-density polypropylene, these panels boast intrinsic properties that enhance their lifespan. Polypropylene is known for its resistance to degradation, ensuring that the panels can withstand various environmental conditions without compromising their performance.Low Maintenance Needs: The smooth surface of PP Honeycomb Panels makes them resistant to stains and easy to clean. This low-maintenance characteristic prevents the accumulation of dirt and grime, reducing the need for frequent maintenance and preserving the panels' appearance and functionality over time.

Resistance to Wear and Tear, Impact, and Environmental Factors

Impact Resistance: One of the standout features of PP Honeycomb Panels is their ability to absorb and resist impacts. This resilience makes them ideal for applications where heavy use or accidental bumps and knocks are common. The panels can handle substantial force without deforming or cracking, ensuring long-term durability.Wear and Tear: The panels' robust construction helps them withstand regular wear and tear, making them suitable for high-traffic areas or frequently used surfaces. Their resistance to scratching and scuffing maintains their aesthetic appeal and structural integrity even after extensive use.Environmental Factors: PP Honeycomb Panels are designed to endure various environmental conditions. They are resistant to moisture, UV radiation, and extreme temperatures, which prevents issues like warping, fading, or deterioration. This makes them an excellent choice for both indoor and outdoor applications, where they can perform reliably across different climates.

Case Studies and Examples of Long-Term Use

Automotive Sector: The automotive industry relies on PP Honeycomb Panels for interior components like door panels and dashboards. These panels have been praised for their durability under constant use and exposure to sunlight and temperature fluctuations. Real-world cases show that they maintain their structural integrity and appearance well beyond the expected lifespan.Packaging Applications: In packaging, PP Honeycomb Panels are used for protective cases and pallets. The panels’ resistance to impacts and environmental factors ensures that they continue to provide reliable protection for goods during transportation and storage. Users have reported that these panels significantly reduce the need for replacements, highlighting their cost-effectiveness over time.

4. Maintenance and Upkeep

5. Environmental Impact and Sustainability

Choosing PP Honeycomb Panels from Polyreflex means opting for a product that combines strength with eco-friendliness, delivering exceptional performance while supporting sustainable practices. For more information or to request a quote, contact Polyreflex today and discover how our high-quality panels can meet your needs effectively and efficiently.