Customization plays a crucial role in maximizing the effectiveness of PP Honeycomb Panels. Different industries, from automotive to construction, have unique requirements, whether it' s in terms of thickness, surface finish, or fire resistance. By customizing these panels to meet specific demands, businesses can enhance performance, efficiency, and product longevity, ensuring that they get the most out of this innovative material.

Why Customization Matters

Key Customization Features for Industry-Specific Needs

1. Thickness and Weight Customization

The ability to adjust the thickness and weight of PP Honeycomb Panels is vital for meeting specific load-bearing or weight-saving requirements across different industries. For example, in the automotive sector, lightweight panels are essential for reducing vehicle weight without compromising strength. In contrast, industries like construction may require thicker panels for additional structural support. By fine-tuning the panel' s thickness and weight, businesses can ensure the right balance of durability and efficiency for their specific applications.

2. Surface Finishes and Treatments

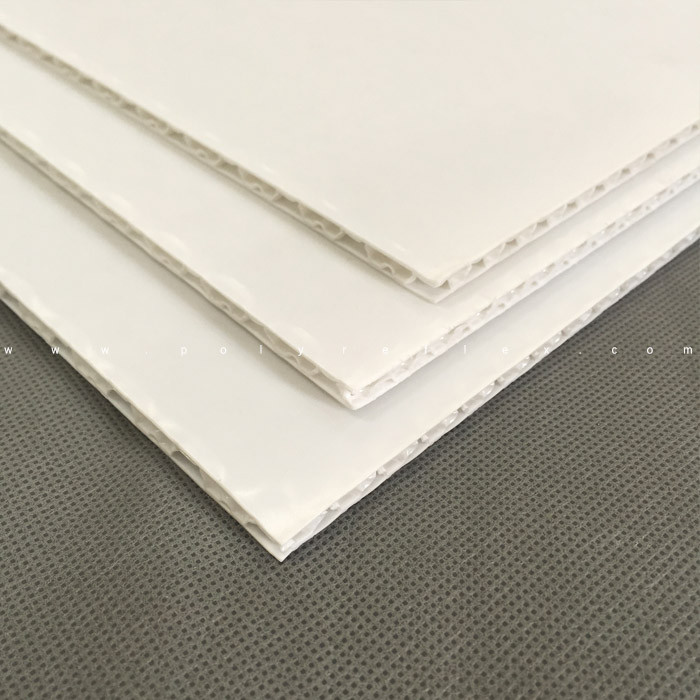

Surface customization plays a significant role in optimizing PP Honeycomb Panels for their intended use. Depending on the application, surfaces can be treated with matte, glossy, or textured finishes. For instance, a matte finish is ideal for packaging applications where scratch resistance is key, while a glossy finish might be preferred for furniture or display designs. Additional treatments, such as UV resistance or anti-static coatings, can be applied based on industry needs, ensuring the panels maintain their integrity even under challenging conditions.

3. Color and Aesthetic Options

Customizing the color of PP Honeycomb Panels is not only about aesthetics but also about meeting specific industry demands. In sectors like interior design or corporate branding, color options allow companies to match their visual identity while maintaining the functional benefits of the panels. From neutral tones for industrial uses to vibrant colors for retail or signage applications, Polyreflex can provide panels in a wide range of shades to suit any purpose.

4. Thermal and Fire Resistance Customization

For industries like construction or transportation, where safety is paramount, customizing PP Honeycomb Panels to enhance thermal and fire resistance is critical. These panels can be engineered to meet stringent fire safety standards, ensuring protection against heat and flames in high-risk environments. In addition, thermal resistance customization helps regulate temperatures in various settings, making them ideal for insulation or as barriers in construction projects.

5. Precision Cutting and Sizing

Precise measurements are often required for industry-specific applications, especially in fields like aerospace and automotive manufacturing. PP Honeycomb Panels can be cut to exact specifications using CNC cutting technology, ensuring each panel fits perfectly within the intended design. Whether it' s a complex shape or exact dimensions, precision cutting allows for seamless integration into a variety of projects, improving both efficiency and overall performance.

Industry-Specific Examples of Custom PP Honeycomb Panels

1. Automotive and Transportation

In the automotive and transportation industries, weight reduction is a critical factor for improving fuel efficiency and reducing emissions. Custom PP Honeycomb Panels are ideal for car interiors, as well as the walls and floors of buses and trains, providing a lightweight yet strong material that meets stringent safety and performance standards. These panels can be tailored to specific thicknesses and reinforced for enhanced impact resistance, making them perfect for demanding transportation environments.

5. Marine and Aquatic Applications

The marine and aquaculture industries benefit from the water-resistant and corrosion-proof nature of PP Honeycomb Panels. These panels can be customized to withstand harsh aquatic environments, making them ideal for boat construction, floating platforms, and aquaculture cages. Their durability and resistance to chemicals and saltwater ensure long-lasting performance, even under extreme conditions.

How Polyreflex Offers Customization for Different Industries

Choosing the Right Custom Solution for Your Industry