With over 18 years of experience, Polyreflex is a trusted manufacturer of HDPE boards, offering tailored solutions to meet the unique needs of every customer. Our expertise ensures you get the best quality and the right thickness for your specific application, helping you make informed decisions for optimal results.

Durability: HDPE boards are known for their exceptional toughness and long-lasting performance. They are highly resistant to wear and tear, making them ideal for high-stress applications that require durability over time.Chemical Resistance: One of the standout features of HDPE boards is their resistance to a wide range of chemicals, including acids, alkalis, and solvents. This makes them suitable for use in environments where exposure to corrosive substances is common.Weatherproofing: HDPE boards are highly resistant to environmental factors such as moisture, UV radiation, and extreme temperatures. They do not warp, crack, or degrade when exposed to outdoor elements, making them perfect for both indoor and outdoor applications.Sustainability: HDPE boards are eco-friendly and recyclable, offering a sustainable solution for industries seeking to reduce their environmental impact. This makes them a responsible choice for companies looking to adopt green manufacturing practices.

2. The Role of Thickness in HDPE Boards

The thickness of HDPE boards plays a critical role in determining their overall performance and suitability for different applications. The right thickness ensures that the material can handle the specific requirements of an application, including strength, impact resistance, load-bearing capacity, and flexibility.

Impact on Strength and Load-Bearing Capacity

As the thickness of an HDPE board increases, so does its ability to withstand heavy loads and stress. Thicker boards offer superior strength, making them ideal for heavy-duty applications like construction, industrial manufacturing, and material handling. For example, in building infrastructure or manufacturing machinery parts, thicker HDPE boards provide the necessary strength to support large loads without bending or breaking.

Influence on Impact Resistance

Impact resistance is another important factor affected by the thickness of HDPE boards. Thicker boards are better equipped to absorb shocks and resist impacts, making them ideal for high-stress environments where heavy equipment or vehicles are used. In applications such as industrial flooring or construction barriers, thicker HDPE boards offer better protection against damage from impact.

Flexibility and Application Suitability

While thicker HDPE boards offer enhanced strength and resistance, thinner boards provide more flexibility. Thinner boards are often preferred for applications that require bending or shaping, such as in the packaging industry or for making flexible storage solutions. Thicker boards may be more rigid, which is beneficial in applications where structural integrity is crucial, but they might not offer the same ease of molding as thinner boards.

Ultimately, selecting the right thickness for your HDPE board application ensures that the material will perform optimally in terms of strength, flexibility, and long-term durability. The thickness should align with the specific demands of the project, considering factors like load, impact, and environmental conditions.

3. How to Determine the Right Thickness for Your Application?

Choosing the right thickness for your HDPE board is crucial for ensuring its optimal performance and longevity. Several factors should be considered to make the best choice for your specific application. Here’s a breakdown of key considerations when selecting the appropriate thickness:

1. Consider the Load and Stress

Different applications place varying levels of stress and load on the HDPE boards. For heavy-duty industrial and construction uses, such as in machinery parts, flooring, or structural components, thicker boards (typically 10-25 mm or more) are often necessary to support the weight and resist deformation under pressure. On the other hand, for applications with lighter stress, such as packaging or storage solutions, thinner boards (3-6 mm) may suffice. Assessing the weight, impact, and mechanical stress your HDPE boards will endure is essential for determining the correct thickness.

3. Durability and Longevity

The lifespan of your HDPE boards is another factor closely tied to their thickness. Thicker boards tend to be more durable and resistant to wear, ensuring that they perform well over time, even in demanding applications. If the application requires the boards to withstand constant use, frequent handling, or long-term exposure to tough conditions, selecting a thicker option can significantly extend the product's longevity. Conversely, if the board is only used for a short-term or light-duty application, a thinner board may be sufficient while providing cost savings.

By carefully evaluating these factors—load and stress, environmental conditions, durability, and cost—you can confidently select the ideal thickness for your HDPE board application, ensuring it meets all performance requirements and provides long-lasting value.

4. Common Applications and Recommended Thickness for HDPE Boards

HDPE boards are incredibly versatile, finding use in a wide variety of applications across different industries. The right thickness ensures optimal performance, durability, and cost-effectiveness. Below, we explore some common applications of HDPE boards and the recommended thickness for each:

2. Construction and Infrastructure

In construction, HDPE boards are used for applications such as geomembranes, pipes, barriers, and panels. For geomembranes, which are used for waterproofing and environmental protection, a thickness of 1 mm to 3 mm is commonly used. However, for structural components like pipes and construction panels, thicker boards in the range of 8 mm to 25 mm are typically recommended. These thicker boards offer superior strength and resistance to heavy loads, chemical exposure, and environmental wear, which are critical in construction and infrastructure applications.

3. Agriculture and Irrigation Systems

HDPE boards play a crucial role in agricultural applications, such as liners, covers, and barriers for irrigation systems. For agricultural liners, which need to withstand soil pressure, UV exposure, and chemical interactions, a thickness of 1 mm to 3 mm is often suitable. In more demanding applications like pond liners or large-scale irrigation systems, thicker boards of 5 mm to 12 mm can provide the necessary strength and durability. These thicker boards ensure long-term performance, even under heavy stress and exposure to environmental factors.

4. Industrial Manufacturing

In industrial manufacturing, HDPE boards are often used for producing components and machinery parts. These applications typically require boards with higher strength and impact resistance to handle heavy loads and mechanical stress. For standard manufacturing parts, a thickness range of 6 mm to 15 mm is commonly used, providing the balance of strength, flexibility, and durability. For high-stress components, such as those exposed to heavy machinery or continuous movement, boards of 15 mm to 25 mm thickness are recommended for added strength and longevity.

In each of these applications, selecting the right thickness is essential to ensure that the HDPE boards meet the functional, safety, and longevity requirements specific to the task. By considering the nature of the application and the stresses it will encounter, you can determine the optimal thickness to achieve the best performance at the most cost-effective price.

5. Polyreflex HDPE Board Options and Customization

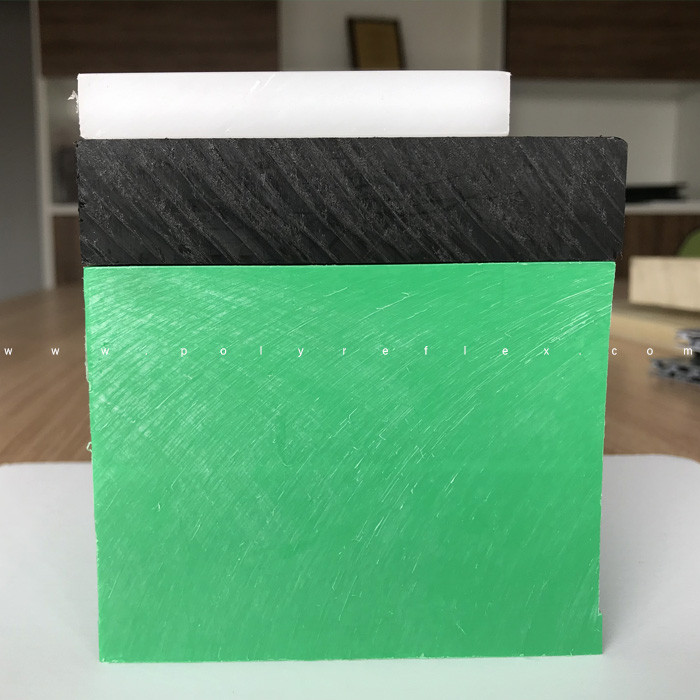

At Polyreflex, we take pride in offering a wide range of HDPE boards to meet the diverse needs of various industries. Our boards come in different thicknesses, sizes, and colors, ensuring that you can find the perfect solution for your application. Whether you require standard thicknesses for general applications or custom solutions for specific requirements, we are committed to providing the best quality and service.

HDPE Board Thickness Options

Polyreflex offers HDPE boards in a variety of thicknesses, from 1 mm to 25 mm, allowing you to choose the right level of strength, flexibility, and durability for your project. Whether you need a thin, flexible board for packaging or a thicker, more rigid option for construction or industrial use, we have the right products to suit your needs.

Size: We can cut boards to the specific dimensions required for your application, ensuring perfect fitment and minimal waste.Color: Choose from a range of colors, or request custom colors to match your branding or project specifications.Additional Features: Depending on your needs, we can add features such as UV resistance, anti-slip surfaces, or special surface treatments to improve the functionality of your HDPE boards.

Tailored Solutions for Your Needs

At Polyreflex, we believe in providing more than just a product – we offer solutions. Our team of experts is ready to work with you to find the best HDPE board options and customize them to your exact specifications. Whether you need boards for industrial applications, construction, or agriculture, we can help you select the right thickness, size, and features to meet your specific needs.