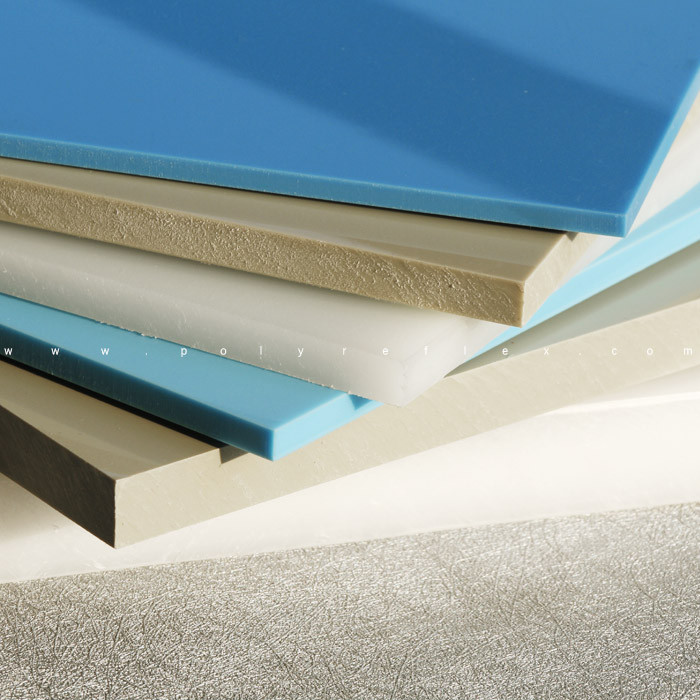

What is Polypropylene (PP) Board?

Key Benefits of Polypropylene (PP) Board

Durability & Impact Resistance: Polypropylene (PP) boards are known for their exceptional durability and impact resistance. Their robust structure makes them ideal for demanding applications in industries such as automotive, manufacturing, and construction, where materials are subject to rough handling and physical stress. The ability to withstand impacts without cracking or breaking enhances the longevity of products made from PP boards.

Chemical Resistance: One of the standout features of PP boards is their excellent resistance to chemicals, including acids, alkalis, and solvents. This makes them perfect for use in harsh environments like laboratories, chemical processing plants, and industrial facilities, where exposure to corrosive substances is common. The material remains stable and unaffected by most chemicals, ensuring its durability and functionality in such demanding conditions.

Lightweight & Easy to Handle: Despite their strength and resistance properties, PP boards are lightweight, making them easy to handle, transport, and fabricate. This characteristic reduces labor costs and increases efficiency in manufacturing and installation processes. The ease of handling also makes PP boards a preferred choice for a variety of applications that require quick assembly or customization.

Moisture Resistance & Low Water Absorption: PP boards are highly resistant to moisture and have low water absorption, which makes them suitable for use in wet or humid conditions. This property is particularly beneficial in applications like marine, agriculture, or outdoor installations, where exposure to water and moisture could otherwise lead to material degradation. The water-resistant nature of PP boards ensures their long-term performance and reliability in these environments.

Environmental Sustainability: Polypropylene is a recyclable material, making PP boards an eco-friendly option compared to other plastics like PVC. As industries increasingly focus on sustainability, choosing PP boards helps reduce environmental impact. Their recyclability contributes to reducing waste, aligning with green initiatives and promoting a more sustainable manufacturing process.

Applications of Polypropylene (PP) Board

1. Chemical and Industrial Storage Tanks

Polypropylene (PP) boards are widely used in the manufacturing and industrial sectors due to their durability and strength. These boards are employed in the creation of machine guards, containers, and tanks, where their resistance to impact, chemicals, and moisture is essential for long-term performance. PP boards are also used in factory settings for protective barriers and operational parts, providing a reliable solution that meets the rigorous demands of industrial environments.

2. Machinery Components and Protective Barriers

In industrial settings, PP boards are fabricated into durable components like machine guards, workbenches, and impact-resistant barriers. Their toughness and resistance to abrasion make them ideal for creating long-lasting protective solutions for heavy machinery.

3. Agriculture and Aquaculture Equipment

In agriculture, PP boards are used for fabricating troughs, bins, and silos, as they can withstand prolonged exposure to water, fertilizers, and pesticides. In aquaculture, they serve as durable panels for fish tanks and water reservoirs due to their resistance to algae growth and corrosion.

4. Medical and Laboratory Equipment

In the medical and laboratory fields, PP boards are valued for their chemical resistance, ease of cleaning, and sterilization properties. They are commonly used in cleanrooms, laboratory benches, and as protective barriers. Their non-toxic nature and ability to withstand exposure to harsh chemicals make them ideal for environments where hygiene and safety are paramount. PP boards also offer durability in the face of frequent cleaning and disinfection, making them a trusted material for medical applications.

Why Choose Polyreflex PP Boards?

Quality Control and Standards

Polyreflex is committed to maintaining the highest standards of quality. We use advanced production techniques and rigorous quality control processes to ensure that every PP board we produce meets or exceeds international standards. Our boards undergo thorough testing for strength, durability, chemical resistance, and other critical properties, ensuring consistent and reliable performance. By choosing Polyreflex, you can be confident that you’re receiving a top-quality product that will stand the test of time.

Customer Service & Support

We pride ourselves on our customer-first approach, offering comprehensive support throughout your entire experience with us. From pre-sale consultations to help you choose the right product for your needs, to post-sale assistance ensuring your satisfaction, our team is always available to provide expert advice and assistance. At Polyreflex, we believe in building long-term relationships with our customers, and we're here to support you every step of the way.