In the fast-paced beverage industry, where speed, durability, and cost-efficiency are crucial, logistics plays a key role in ensuring products reach their destinations in perfect condition. Traditional packaging materials like cardboard often fall short when it comes to handling moisture, reusability, and protection. That’s why more and more beverage distributors are turning to PP corrugated sheets—a lightweight, durable, and reusable solution that significantly enhances logistics performance.

In this article, we'll explore what

PP corrugated sheets are, how they're used in beverage logistics, and how they help companies improve their supply chain efficiency and reduce costs.

What Are PP Corrugated Sheets?

PP corrugated sheets are made from polypropylene (PP), a thermoplastic polymer known for its durability, flexibility, and resistance to chemicals and moisture. These sheets consist of a fluted core layer sandwiched between two flat outer layers, forming a lightweight but highly rigid structure—similar to cardboard, but made entirely from plastic.

Waterproof and Weather-Resistant

Unlike cardboard, PP corrugated sheets are:

Waterproof and weather-resistantReusable for multiple logistics cyclesNon-toxic and 100% recyclableLightweight yet strong enough to carry heavy beverage loads

At Polyreflex, we offer custom PP corrugated sheets in a variety of thicknesses, sizes, colors, and surface treatments (including corona treatment for printing), tailored to fit your beverage distribution needs.

Applications in Beverage Distribution

PP corrugated sheets have become a versatile packaging and logistics solution in the beverage industry. Here’s how distributors commonly use them:

1. Layer Pads for Bottled Beverages

Placed between layers of bottles or cans during palletizing, PP corrugated layer pads provide stability and prevent movement or toppling during transport. They're especially useful for PET bottles, glass bottles, and aluminum cans.

2. Bottle Dividers and Inserts

Cut and slotted PP sheets are used inside crates and boxes to separate individual bottles, minimizing contact and reducing the risk of breakage.

PP Corrugated Sheets Layer Pads

PP Corrugated Sheets Crate Liners

3. Crate Liners and Box Linings

These sheets can be inserted into returnable plastic crates to protect beverage labels from rubbing or moisture during transportation.

4. Pallet Liners and Slip Sheets

As pallet liners, PP corrugated sheets keep beverage packaging elevated and protected from dust, dirt, or moisture on the warehouse floor or during shipping.

How PP Corrugated Sheets Improve Logistics Efficiency

Switching to PP corrugated sheets offers beverage distributors a wide range of logistical advantages:

1. Reduced Breakage and Product Loss

By stabilizing and separating bottles, PP sheets minimize the movement that often causes breakage during transport—especially for glass or fragile containers.

2. Lightweight, Lower Shipping Costs

PP corrugated sheets are much lighter than wood or solid plastic panels, helping reduce the total shipment weight and lower fuel consumption.

3. Reusable and Long-Lasting

Unlike single-use cardboard, PP sheets can be reused dozens of times in return logistics, dramatically reducing material waste and packaging costs over time.

4. Moisture and Chemical Resistance

Ideal for cold chain logistics, PP corrugated sheets do not absorb water or degrade in humid environments, making them perfect for cold beverages or refrigerated transport.

5. Improved Handling and Cleanliness

Smooth surfaces make PP sheets easy to clean, sanitize, and handle—an essential benefit in beverage distribution where hygiene is a top priority.

Case Study: Beverage Distributor Reduces Losses by 30%

A large bottled juice distributor in South America partnered with Polyreflex to switch from cardboard dividers to custom-cut PP corrugated bottle inserts. The result?

Breakage during transport dropped by 30%Packaging reuse increased from 2 to over 20 cyclesAnnual savings of over $50,000 on packaging materialImproved customer satisfaction due to reduced damage claims

This case highlights how investing in better packaging solutions—like PP corrugated sheets—can directly benefit the bottom line.

Why Choose Polyreflex as Your PP Corrugated Sheet Supplier?

With 18 years of manufacturing experience, Polyreflex is one of China's most trusted producers of high-quality PP corrugated sheets. We understand the unique requirements of the beverage industry and offer:

Custom Colored PP Corrugated Sheets

Corona Treatment PP Corrugated Sheets

Customized sizes, colors, and die-cut shapesCorona treatment for better printabilityQuick turnaround times and global shippingProfessional support from design to delivery

Whether you need layer pads for bottles, crate liners, or custom dividers, Polyreflex can supply the right PP corrugated sheet solution for your beverage distribution needs.

Conclusion: Smarter Beverage Logistics Starts Here

Polyreflex PP Corrugated Sheets

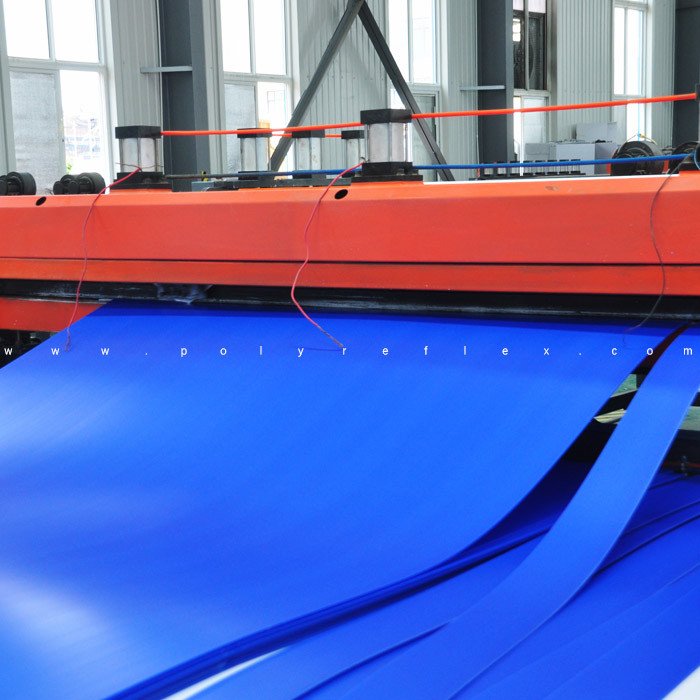

Polyreflex PP Corrugated Sheets Production Lines

PP corrugated sheets are transforming beverage logistics by making transport safer, cleaner, and more cost-effective. Their reusability, moisture resistance, and lightweight design offer clear advantages over traditional materials like cardboard.

Ready to upgrade your beverage packaging?