Polyreflex PP (Polypropylene) Honeycomb Panel

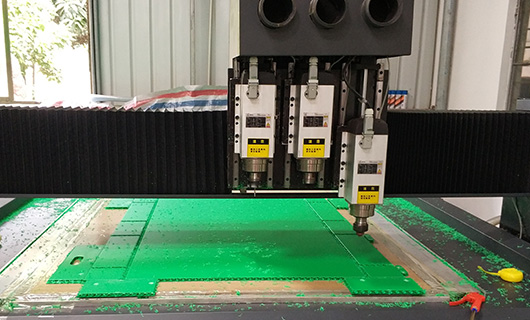

features an innovative sandwich design, with a honeycomb-structured core layer and optional surface finishes, either bubble-textured or smooth.

Made entirely from polypropylene, Polyreflex plastic honeycomb panels offer a robust and stable core layer. These panels provide numerous benefits, including lightweight construction, chemical and impact resistance, high load-bearing capacity, easy machinability, and full recyclability. Unlike paper honeycomb panels, which are prone to water damage and humidity, or aluminum honeycomb panels, which can be costly and lack sound insulation and corrosion resistance, polypropylene honeycomb panels overcome these limitations.

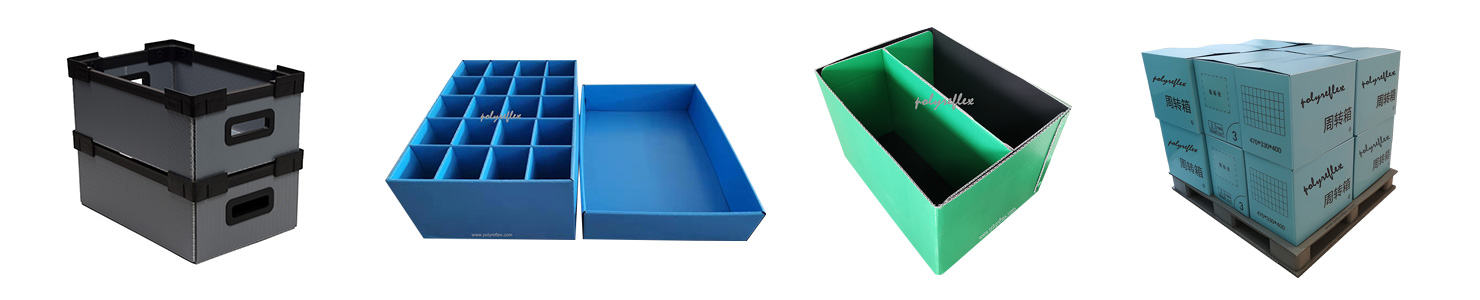

Thanks to their lightweight and versatile properties, these panels are extensively utilized across various industries, such as automotive, logistics, warehousing, packaging, advertising, and construction.