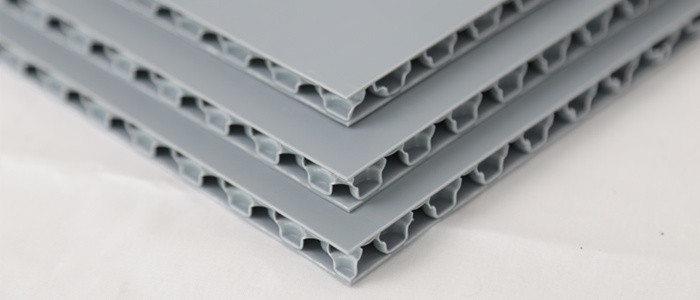

1. Material Selection: The first step is to choose the right material for the box, taking into account factors such as thickness, weight, color, and specific performance characteristics like anti-static, flame retardancy, or cold resistance.

Production of PP Corrugated Sheet

Production of PP Bubble Board

Production of PP Honeycomb Panel

2. Cutting the Material: The material sheets are shaped through methods like die-cutting, hot pressing, or CNC engraving. For self-supporting boxes, this stage can also serve as the final assembly, as these boxes can interlock and function effectively without additional parts.

3. Box Assembly: For boxes that are not self-supporting, various methods are employed to join the components, such as using rivets, staples, ultrasonic welding, or seamless welding. These techniques improve the structural integrity and longevity of the boxes.

4. Handle, Closure, and Stacking Features: Handles can be incorporated to make carrying easier, while Velcro closures offer simple access and compact storage when the box is not in use. To improve stacking efficiency and durability, reinforced corners and edges can be added.

5. Interior Protection: To safeguard the items within and accommodate robotic handling systems, interior dividers can be inserted. These dividers help secure and organize the contents, preventing damage during transportation.

6. Printing and Branding: For companies aiming to promote their brand or display product information on the box, a variety of printing options are available, such as silkscreen, digital printing, CMYK printing, and laser marking. Additionally, techniques like punching or saw cutting can be used to showcase the company's logo or corporate identity (CI) on the exterior.