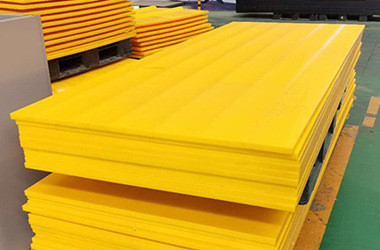

Polyreflex Ultra-high Molecular Weight Polyethylene Sheet

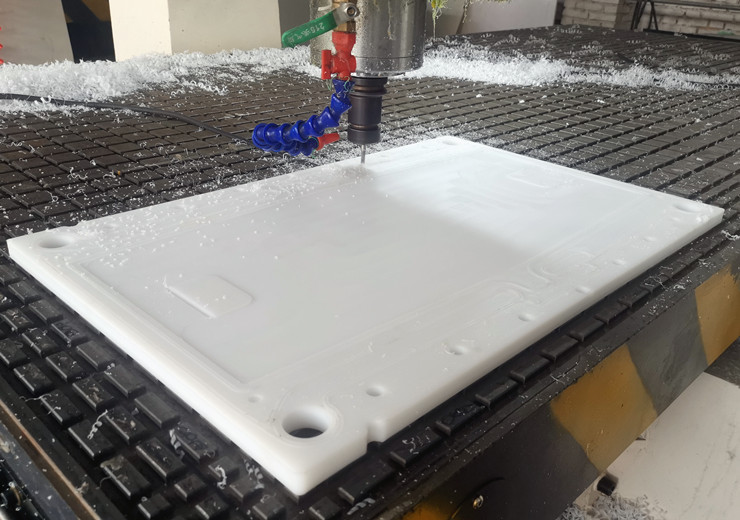

also known as UHMWPE sheet or UPE sheet. It is an unbranched linear polyethylene with a molecular weight of more than 1.5 million that is manufactured through compression molding process.

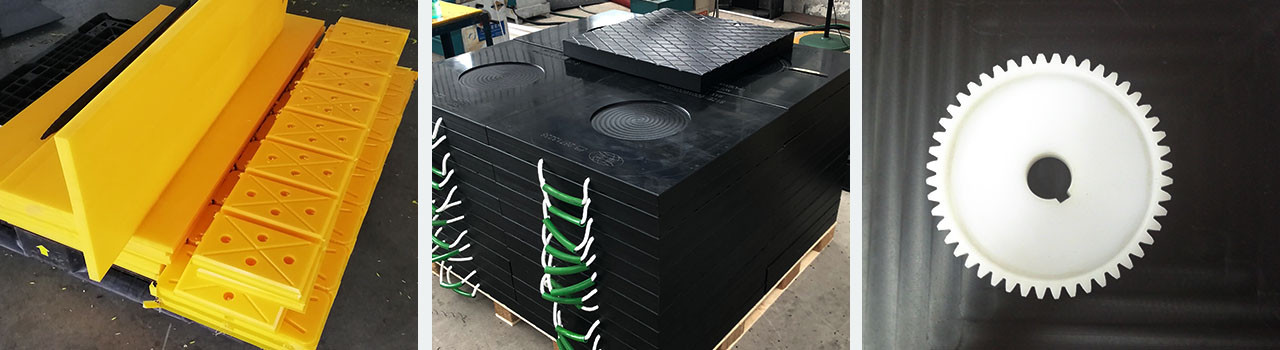

UHMWPE is a thermoplastic engineering plastic with a linear structure with excellent comprehensive properties. UHMWPE is a polymer compound that is difficult to process, and has many excellent properties such as super wear resistance, self-lubrication, high strength, stable chemical properties, and strong anti-aging properties.

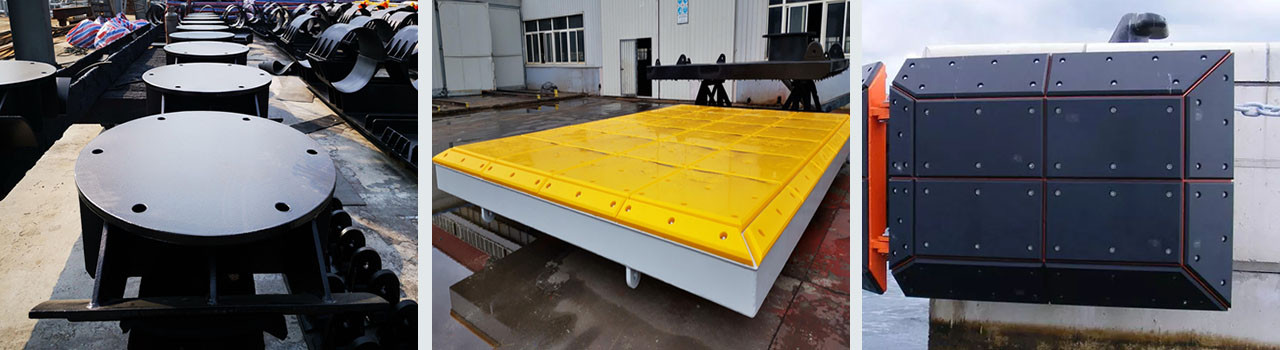

It has shown great advantages in the high-performance engineering plastics market, from mooring lines in offshore oil fields to high-performance lightweight composites. At the same time, it plays a pivotal role in the fields of aviation, aerospace, and maritime defense equipment in modern warfare.