Thermoplastic sheets are integral components in various industries, offering a wide array of applications due to their versatility and durability. Among these thermoplastics, ABS (Acrylonitrile Butadiene Styrene) and HIPS (High-Impact Polystyrene) sheets stand out for their remarkable properties and widespread use. ABS sheets are known for their exceptional strength, impact resistance, and durability, making them a preferred choice in industries such as automotive, electronics, and construction. On the other hand, HIPS sheets also boast impressive strength and versatility, finding applications in packaging, signage, and consumer goods industries. In this article, we delve into the comparison of ABS and HIPS sheets, focusing specifically on their strength characteristics. By understanding the differences between these two materials, readers can make informed decisions when selecting the most suitable thermoplastic for their projects.

ABS (Acrylonitrile Butadiene Styrene) sheets are a type of thermoplastic known for their exceptional properties and versatile applications. Composed of a blend of acrylonitrile, butadiene, and styrene polymers, ABS sheets exhibit a unique combination of strength, impact resistance, and durability.

One of the key properties of ABS sheets is their remarkable strength. These sheets boast high tensile strength, allowing them to withstand considerable mechanical stress without deformation or breakage. This inherent strength makes ABS sheets ideal for applications requiring structural integrity and reliability.

In addition to strength, ABS sheets are also renowned for their outstanding impact resistance. They have the ability to absorb and disperse impact energy, minimizing the risk of damage or fracture upon impact. This property makes ABS sheets suitable for applications where resistance to impact or sudden forces is crucial, such as automotive components, protective equipment, and consumer goods.

Durability is another hallmark of ABS sheets. These sheets exhibit excellent resistance to abrasion, chemicals, and weathering, ensuring long-term performance in diverse environmental conditions. Whether exposed to harsh chemicals in industrial settings or outdoor elements in construction applications, ABS sheets maintain their integrity and functionality over time.

ABS sheets find widespread use across various industries due to their versatile properties. In the automotive sector, ABS sheets are used for manufacturing interior and exterior components, such as dashboards, trim panels, and bumper covers, owing to their strength, impact resistance, and aesthetic appeal. In electronics, ABS sheets serve as housings for electronic devices and enclosures for electrical equipment, providing protection against mechanical stress and environmental factors. Additionally, ABS sheets are utilized in construction for architectural trim, signage, and structural components, benefiting from their durability and ease of fabrication.

HIPS (High-Impact Polystyrene) sheets are a versatile thermoplastic material renowned for their strength, impact resistance, and versatility. Composed of polystyrene with added impact modifiers, HIPS sheets exhibit enhanced toughness and durability compared to standard polystyrene sheets.

One of the primary properties of HIPS sheets is their impressive strength. Despite being lightweight, HIPS sheets possess high tensile strength, allowing them to withstand significant mechanical stress without deformation or breakage. This inherent strength makes HIPS sheets suitable for applications requiring structural integrity and reliability.

In addition to strength, HIPS sheets are known for their exceptional impact resistance. They have the ability to absorb and dissipate impact energy, minimizing the risk of damage or fracture upon sudden force application. This property is particularly advantageous in applications where resistance to impact or mechanical stress is critical, such as packaging, signage, and consumer goods.

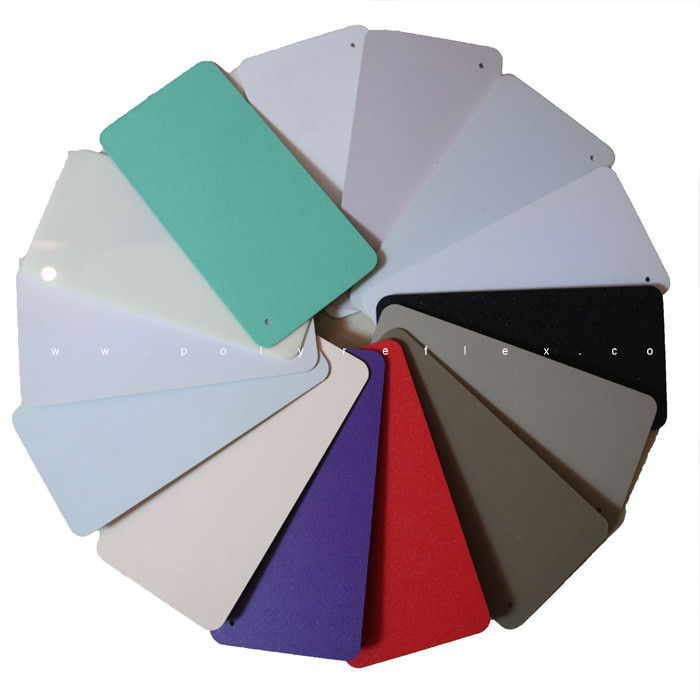

Versatility is another key characteristic of HIPS sheets. These sheets can be easily molded, cut, and formed into various shapes and sizes, making them suitable for a wide range of applications. Whether used in thermoforming processes to create packaging trays and containers or in printing applications for signage and displays, HIPS sheets offer flexibility and adaptability to meet diverse manufacturing needs.

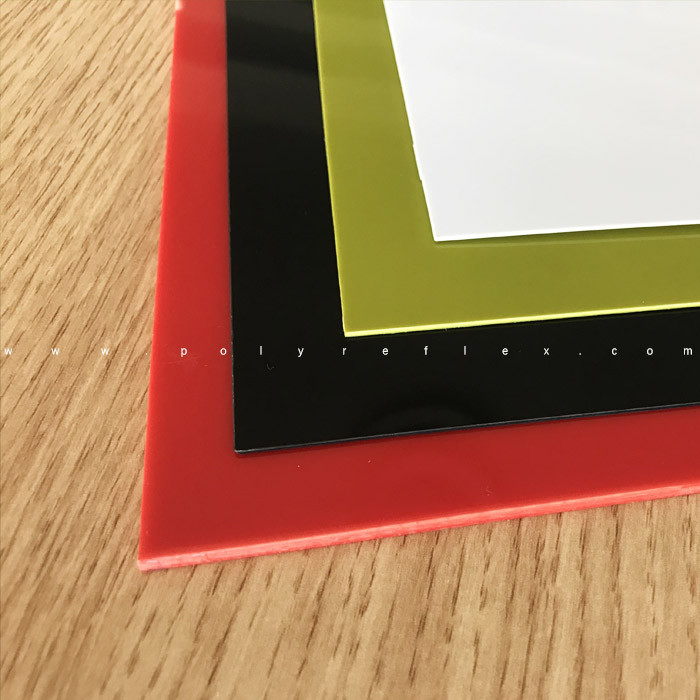

When compared to ABS sheets, HIPS sheets offer similar properties in terms of strength, impact resistance, and versatility. However, HIPS sheets are often preferred in applications where cost-effectiveness and ease of processing are priorities. ABS sheets may offer slightly higher strength and impact resistance, but HIPS sheets provide a more economical solution without compromising performance in many cases.

When comparing the strength characteristics of ABS (Acrylonitrile Butadiene Styrene) and HIPS (High-Impact Polystyrene) sheets, several factors come into play, influencing their performance in various applications.

Examples and Case Studies

Real-world examples and case studies provide valuable insights into the strength capabilities of ABS and HIPS sheets in practical applications. Case studies demonstrating the performance of ABS and HIPS sheets in automotive, electronics, packaging, and construction industries can illustrate their strength under different operating conditions and environmental factors. By analyzing these examples, users can gain a better understanding of how ABS and HIPS sheets perform in real-world scenarios and make informed decisions when selecting materials for their projects.

In conclusion, while both ABS and HIPS sheets offer impressive strength and durability, the specific application requirements and performance criteria will dictate which material is more suitable for a given project. By considering factors such as material composition, manufacturing process, structural design, and real-world performance, users can determine whether ABS or HIPS sheets are the best fit for their applications.

Considerations for Material Selection

When it comes to selecting between ABS (Acrylonitrile Butadiene Styrene) and HIPS (High-Impact Polystyrene) sheets, several factors should be taken into account to ensure the most suitable material is chosen for the specific project requirements.

Guidance on Material Selection

Ultimately, selecting the most suitable material depends on the specific needs and requirements of the project. Consultation with material experts and suppliers can provide valuable guidance and assistance in determining the optimal material choice based on application requirements, environmental conditions, and budget considerations. Consideration of factors such as material composition, manufacturing process, structural design, and real-world performance will help ensure the chosen material meets the desired performance criteria and delivers long-term value and reliability for the project.

In conclusion, carefully evaluating application requirements, environmental conditions, and budget considerations is essential when selecting between ABS and HIPS sheets. By taking these factors into account and consulting with material experts, users can make informed decisions and choose the most suitable material to meet their specific project needs effectively.

Throughout this article, we have explored the unique characteristics of ABS and HIPS sheets, including their material composition, manufacturing process, and real-world applications. While ABS sheets excel in applications requiring superior mechanical strength and durability, HIPS sheets offer a cost-effective solution with comparable performance in many cases.

As for the final verdict on which material is stronger, it ultimately depends on the specific requirements of the project. ABS sheets may offer slightly higher tensile strength and impact resistance compared to HIPS sheets, but the choice between the two materials should consider factors such as application needs, environmental conditions, and budget constraints.

At Polyreflex, we offer a diverse range of thermoplastic sheet options, including ABS and HIPS sheets, to meet the unique needs of our customers. We encourage readers to explore our comprehensive product range and consult with our experts to find the most suitable material for their applications. With our commitment to quality, innovation, and customer satisfaction, Polyreflex is your trusted partner for thermoplastic solutions.

In conclusion, whether you choose ABS or HIPS sheets, Polyreflex is here to provide reliable and high-quality materials to support your projects. Explore the possibilities with Polyreflex and discover the perfect thermoplastic solution for your application needs.