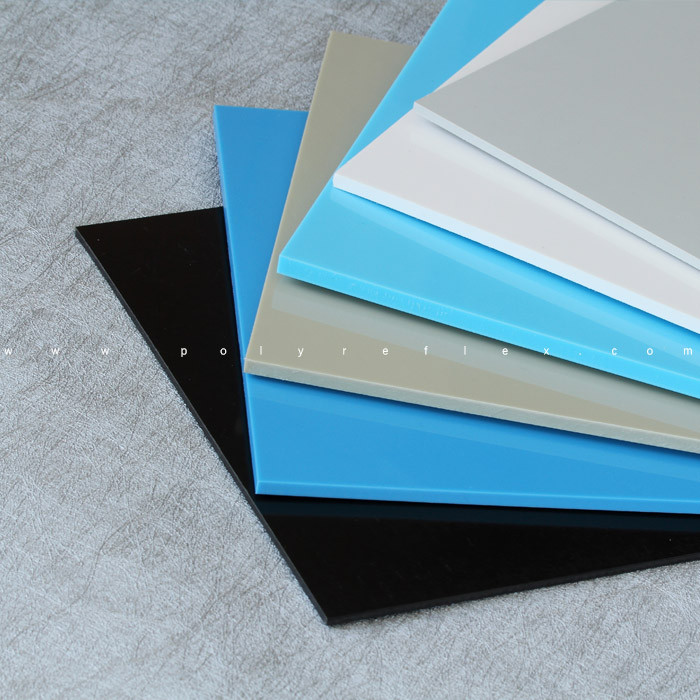

Choosing the right plastic material is crucial to ensuring the success and longevity of your projects. In this article, we will compare HDPE boards with other common plastics, such as PVC, ABS, Polycarbonate, and Polypropylene. By understanding the strengths and limitations of each material, you'll be able to make an informed decision and choose the best option for your requirements.

Durability: HDPE is highly resistant to wear, tear, and physical stress, making it ideal for use in demanding environments. Its robustness ensures that products made from HDPE can withstand harsh conditions, from extreme temperatures to heavy impacts.Flexibility: Despite its strength, HDPE remains flexible enough to be molded into various shapes and sizes, making it suitable for custom applications in many industries. This flexibility allows it to be used in a wide range of products, from rigid boards to more flexible sheets.Impact Resistance: HDPE is highly resistant to impact, making it ideal for applications where durability is a priority. It can absorb significant amounts of force without cracking or breaking, ensuring long-lasting performance.Chemical Resistance: One of the standout features of HDPE is its resistance to a wide variety of chemicals, including acids, bases, and solvents. This makes it particularly valuable in industries like agriculture, pharmaceuticals, and manufacturing, where contact with chemicals is frequent.Environmental Sustainability: HDPE is a 100% recyclable material, making it an eco-friendly option compared to other plastics. It is often used in products that require long lifespans and can be recycled into new products once it reaches the end of its useful life. This makes HDPE a sustainable choice for environmentally-conscious businesses.

Comparing HDPE Boards to Other Plastics

When choosing the right plastic material for your project, it's essential to consider the unique properties of different plastics. HDPE (High-Density Polyethylene) is a strong contender, but how does it stack up against other common plastics? Let's compare HDPE boards to PVC, ABS, Polycarbonate, and Polypropylene to understand their strengths and weaknesses in various applications.

HDPE vs PVC (Polyvinyl Chloride):

HDPE vs ABS (Acrylonitrile Butadiene Styrene):

HDPE vs Polypropylene (PP):

Each plastic material has its own set of advantages depending on the application. HDPE stands out for its unmatched durability, impact resistance, and chemical resistance, making it a top choice in industries like construction, packaging, agriculture, and more. While other plastics like PVC, ABS, Polycarbonate, and Polypropylene have their own strengths, HDPE excels when strength, flexibility, and sustainability are essential. Choosing the right material depends on your specific needs, but HDPE is often the ideal choice for demanding, long-lasting applications.

Advantages of HDPE Boards for Specific Industries

HDPE boards offer unique benefits across several industries, thanks to their durability, strength, and resistance to harsh conditions. Here's how they excel in various sectors:

Construction: HDPE boards are used in formwork, liners, and outdoor signage. Their resistance to wear, impact, and UV radiation makes them ideal for long-lasting applications in construction, offering smooth surfaces for concrete pours and robust signage for outdoor environments.

Packaging: Known for their impact resistance, HDPE boards are widely used to create durable containers, pallets, and protective packaging. Their ability to withstand heavy use ensures that goods are securely transported and stored without damage.

Agriculture: HDPE boards are favored for greenhouse covers, irrigation systems, and liners due to their resistance to UV radiation and chemicals. These properties help in protecting crops, conserving water, and ensuring long-term durability in agricultural environments.

Automotive & Industrial: With a high strength-to-weight ratio, HDPE boards are perfect for automotive components and industrial machinery parts. They provide a lightweight yet strong solution, enhancing durability and performance in demanding environments.

These benefits make HDPE boards a versatile choice, offering long-lasting solutions across a variety of applications.

How to Choose Between HDPE Boards and Other Plastics

Choosing between HDPE and other plastics largely depends on your specific project requirements. If you need a material that combines high strength with flexibility, chemical resistance, and environmental sustainability, HDPE boards are often the best choice. For example, in industries like agriculture, packaging, and construction, where durability and resistance to harsh elements are essential, HDPE will perform reliably.

However, if your project requires transparency or rigid structural integrity, materials like Polycarbonate or ABS may be more suitable. Polycarbonate, for instance, offers transparency and high strength but might not perform as well in harsh chemical environments or with UV exposure.

Tips for Consulting with Manufacturers:

1. Discuss Specific Needs: When in doubt, reach out to a manufacturer like Polyreflex to discuss your project’s unique requirements. Provide as much detail as possible about the conditions your material will be exposed to, the mechanical properties needed, and your budget constraints.

2. Request Samples: Many manufacturers, including Polyreflex, offer samples of their materials so you can test their performance in real-world conditions before making a large investment.

3. Consider Custom Solutions: In some cases, manufacturers can provide customized solutions that combine multiple plastics or add coatings for enhanced properties. Working closely with an expert ensures you find the best material for your specific needs.

Choosing the right plastic for your project can seem challenging, but by carefully considering factors like strength, flexibility, chemical resistance, environmental impact, and cost, you can make an informed decision. HDPE boards are an excellent option for many industries, but it's important to evaluate all available materials to ensure you select the most suitable one for your application. Don't hesitate to consult with experienced manufacturers like Polyreflex to guide you in making the right choice for your project.

At Polyreflex, we are committed to providing top-quality HDPE boards tailored to meet your specific needs. Whether you require high-strength solutions for industrial applications or sustainable materials for environmentally-conscious projects, we've got you covered.

Contact us today for more information or to request a quote. Let Polyreflex be your trusted partner in delivering reliable and innovative HDPE solutions for your business.