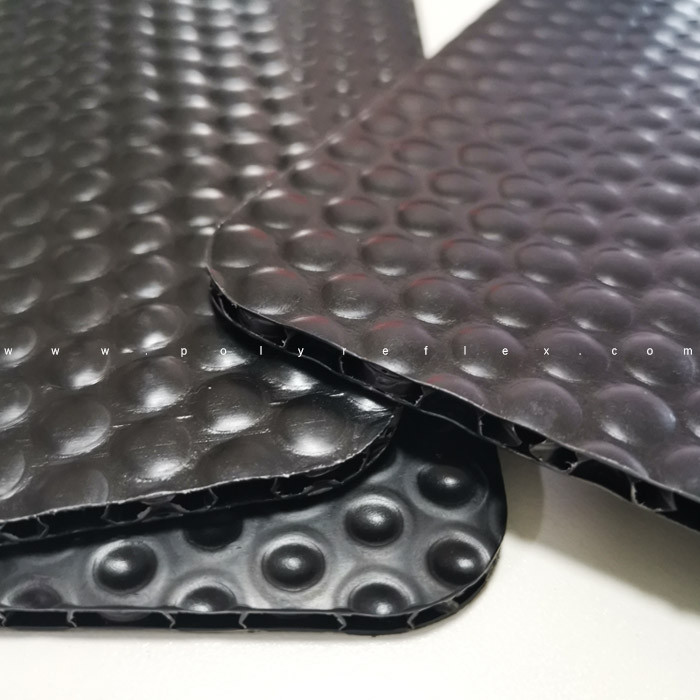

Structure of PP Bubble Board

Top surface layer – Flat and smooth for printing, lamination, or weldingBubble core layer – A middle layer filled with air bubbles, reducing weight while maintaining rigidityBottom surface layer – Similar to the top, for structural balance

Key Advantages of PP Bubble Board

1. Lightweight yet Strong

The bubble core reduces the overall weight by up to 40% compared to solid PP sheets, without compromising on strength or stiffness.

2. Excellent Impact Resistance

The air-filled bubble structure absorbs shocks effectively, making it ideal for protective packaging and automotive interiors.

3. Waterproof and Chemical Resistant

PP material is naturally resistant to moisture, oil, and most chemicals — suitable for outdoor and harsh environments.

4. Eco-Friendly and Recyclable

Made from 100% polypropylene, PP Bubble Board is fully recyclable and free from harmful substances like heavy metals or halogens.

5. Thermoformable and Easy to Process

It can be easily cut, CNC-machined, welded, or thermoformed into various shapes and components.

6. Printable Surface

The flat surface allows for screen printing, digital printing, and lamination, making it suitable for signs and branding.

7. Customizable

Available in a wide range of thicknesses (2mm to 15mm), colors, surface textures, and additional treatments like corona or anti-UV.

What Traditional Materials Can PP Bubble Board Replace?

1. Plywood and MDF (Medium Density Fiberboard)

Used in trunk floors, door panels, and cargo liners, plywood and MDF are heavy and prone to moisture damage. PP Bubble Board offers a lighter, waterproof, and recyclable alternative with similar strength.

2. Corrugated Paperboard

Widely used in packaging, corrugated cardboard is not durable in humid conditions and is typically single-use. PP Bubble Board provides a reusable, moisture-resistant solution with higher impact strength.

3. Solid Polypropylene or Polyethylene Sheets

Although solid plastic sheets are strong, they are heavier and more expensive. PP Bubble Board achieves comparable rigidity with significantly less weight and material cost.

4. PVC Foam Board

Often used in signage and interior panels, PVC foam boards are heavier and less environmentally friendly. PP Bubble Board is halogen-free, more eco-conscious, and easier to recycle.

5. Aluminum Composite Panels (ACP) in Non-Structural Applications

In temporary partitions or interior auto components, ACP is often over-engineered. PP Bubble Board serves as a cost-effective, easier-to-process alternative that is also recyclable.

Applications of PP Bubble Board

Automotive trunk floors, door panels, battery protection coversReusable packaging boxes and pallet sleevesProtective lining for tool cases and transport containersOutdoor advertising boards and exhibition panelsConstruction floor protection and wall cladding