Search This Supplers Products:China manufacturer lightweight plastic corrugated sheets for sign and packaging boxesChina manufacturer good impact strength lightweight pp honeycomb panel for van lining pallet boxChina manufacturer durable plastic pallet container sleeve packs logistics turnover packagingChina manufacturer thermoplastic TPO sheet for automotive floor mats trunk mats truck bed matsChina manufacturer thermoplastic ABS sheet for thermoforming vaccum forming injection moldingChina manufacturer corrosion resistant PP sheet HDPE sheet for chemical industry and aquaculture

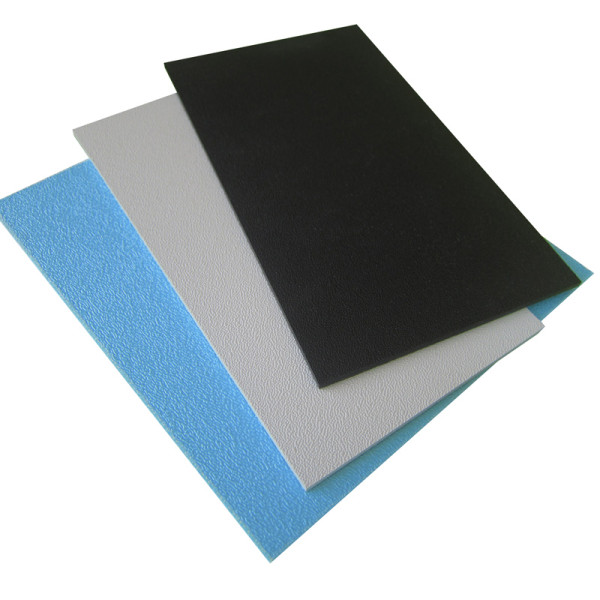

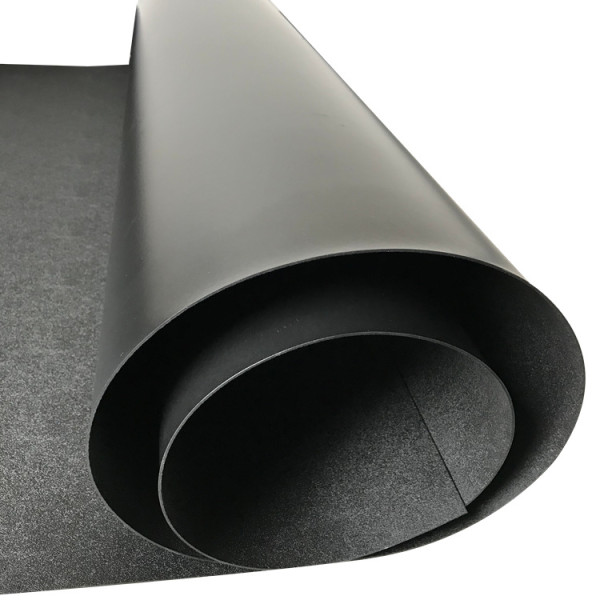

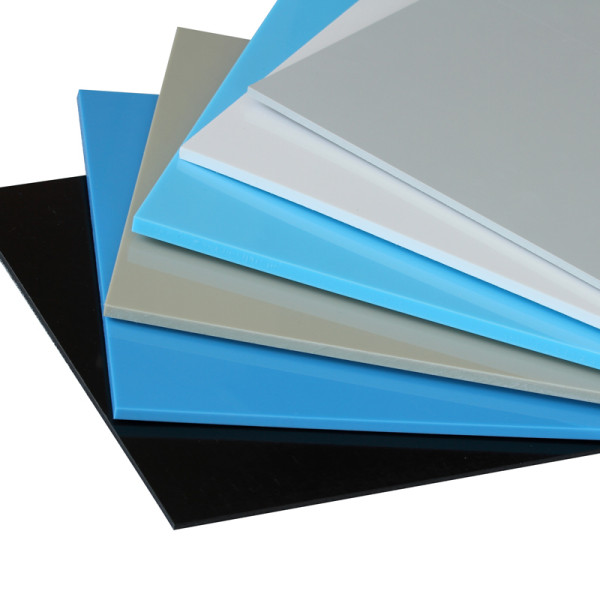

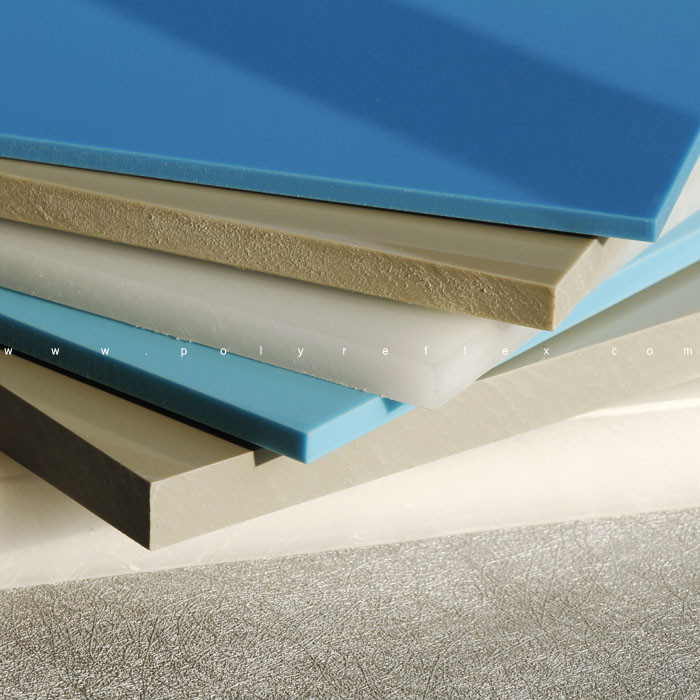

What Are the Types of Thermoplastic Sheets?

sourcehttps://www.polyreflex.com/

publisherPolyreflex

time2024/03/05

- Discover the diverse world of thermoplastic sheets and their myriad applications. Learn about the different types of thermoplastic sheets, their uses, and find a reliable manufacturer for your thermoplastic sheet needs.

- Packaging: HDPE sheets are commonly utilized in packaging applications due to their excellent strength, flexibility, and chemical resistance. They are used for manufacturing bottles, containers, and packaging films for food, beverages, pharmaceuticals, and personal care products.

- Construction: In the construction industry, HDPE sheets serve multiple purposes, including as liners for ponds, reservoirs, and landfills due to their impermeability and resistance to moisture. Additionally, HDPE sheets are used in geotextiles, pipes, and fittings for infrastructure projects, thanks to their durability and longevity.

- Agriculture: HDPE sheets play a vital role in modern agriculture, where they are employed as greenhouse coverings, liners for irrigation systems, and protective barriers for crop cultivation. Their impermeability, chemical resistance, and durability contribute to improved crop yields and resource conservation.

- Aquaculture: In the aquaculture industry, HDPE sheets are utilized for constructing fish tanks, floating cages, and containment systems due to their resistance to corrosion, chemicals, and UV radiation. HDPE's durability and low maintenance requirements make it an ideal material for creating sustainable aquaculture environments.

- Construction: PVC sheets are extensively used in the construction industry for various purposes, including cladding, roofing, and insulation. Their durability, weather resistance, and ease of installation make them ideal for exterior applications where protection from the elements is essential.

- Signage: PVC sheets are popularly used for signage and display applications due to their smooth surface finish, excellent printability, and lightweight nature. They are often employed in advertising boards, shop signage, and exhibition displays, providing a durable and cost-effective solution for promoting brands and messages.

- Healthcare: In the healthcare industry, PVC sheets are utilized for manufacturing medical equipment, devices, and components due to their biocompatibility, sterilizability, and resistance to chemicals. They are commonly used for constructing medical tubing, IV bags, and surgical instruments, ensuring patient safety and hygiene.

- Packaging: PP sheets are commonly utilized in the packaging industry for manufacturing containers, trays, and packaging films. Their lightweight nature, durability, and moisture resistance make them ideal for protecting and preserving a wide range of products, including food, beverages, and pharmaceuticals.

- Automotive: In the automotive sector, PP sheets are employed in various interior and exterior components, such as door panels, dashboard trim, and bumper fascia. Their lightweight nature, impact resistance, and ability to withstand harsh environmental conditions make them ideal for automotive applications.

- Medical: PP sheets are also utilized in the medical industry for manufacturing medical devices, laboratory equipment, and disposable medical supplies. Their biocompatibility, sterilizability, and chemical resistance make them suitable for use in healthcare settings where hygiene and safety are paramount.

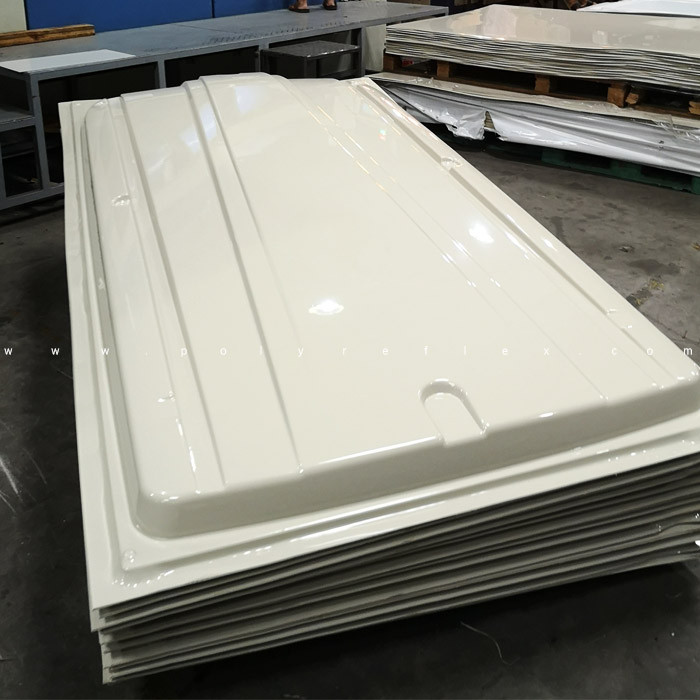

- Automotive: In the automotive industry, TPO sheets are commonly used for manufacturing interior and exterior components, such as bumper covers, door panels, trim pieces, and floor mats. Their flexibility, impact resistance, and weatherability make them ideal for automotive applications where durability and aesthetics are paramount.

- Roofing: TPO sheets are widely utilized in the construction industry for roofing membranes and waterproofing systems. Their excellent weather resistance, flexibility, and heat-weldability make them an ideal choice for roofing applications, providing protection against the elements and ensuring long-term durability.

- Other Outdoor Applications: TPO sheets are also employed in a variety of other outdoor applications, including signage, agricultural equipment, and recreational vehicles. Their weather resistance, flexibility, and ease of fabrication make them suitable for outdoor environments where exposure to UV radiation, moisture, and temperature fluctuations is common.

|

Material

|

Properties

|

Applications

|

|

ABS Sheets

|

ABS sheets exhibit excellent impact resistance, durability, and heat resistance. They are also easily machinable and offer good electrical insulation properties.

|

ABS sheets are commonly used in automotive, electronics, and consumer goods industries for components such as dashboard panels, casings, and toys.

|

HDPE Sheets | HDPE sheets are known for their flexibility, chemical resistance, and environmental friendliness. They offer excellent durability and are impervious to moisture and chemicals. | HDPE sheets find applications in packaging, construction, agriculture, and aquaculture industries due to their versatility and resilience. |

PVC Sheets | PVC sheets are rigid, chemically resistant, and fire retardant. They offer good electrical insulation properties and are lightweight. | PVC sheets are widely used in construction, signage, and healthcare industries for applications such as cladding, advertising boards, and medical equipment. |

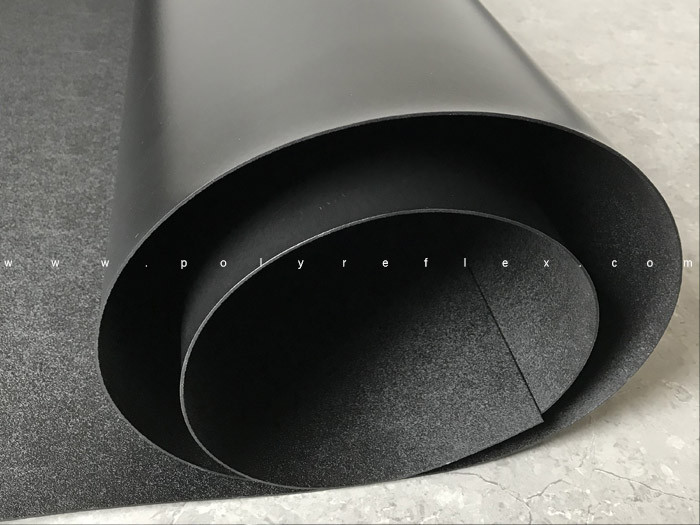

PP Sheets | PP sheets are lightweight, flexible, and offer excellent chemical resistance. They are also moisture-resistant and recyclable. | PP sheets find applications in packaging, automotive, and medical industries for products such as containers, interior components, and medical devices. |

|

TPO Sheets

|

TPO sheets are flexible, weather-resistant, and recyclable. They offer excellent durability and UV resistance.

|

TPO sheets are commonly used in automotive, roofing, and outdoor applications for components such as bumper covers, roofing membranes, and signage.

|

|

Characteristics

|

Comparative Analysis

|

|

Impact Resistance

|

ABS sheets excel in impact resistance, making them suitable for applications requiring protection against mechanical stress.

|

Chemical Resistance | HDPE and PVC sheets offer superior chemical resistance, making them ideal for applications involving exposure to corrosive substances. |

PVC Sheets | PVC sheets are widely used in construction, signage, and healthcare industries for applications such as cladding, advertising boards, and medical equipment. |

Flexibility | PP and TPO sheets exhibit flexibility, making them suitable for applications requiring bending or shaping. |

Weather Resistance | TPO sheets stand out for their weather resistance, making them ideal for outdoor applications where exposure to UV radiation and moisture is common. |

Recyclability | HDPE, PP, and TPO sheets are recyclable, offering environmentally friendly options for sustainable manufacturing practices. |

- Discover Endless Possibilities with Polyreflex Thermoplastic Sheets

- Reach Out Now!