Search This Supplers Products:China manufacturer lightweight plastic corrugated sheets for sign and packaging boxesChina manufacturer good impact strength lightweight pp honeycomb panel for van lining pallet boxChina manufacturer durable plastic pallet container sleeve packs logistics turnover packagingChina manufacturer thermoplastic TPO sheet for automotive floor mats trunk mats truck bed matsChina manufacturer thermoplastic ABS sheet for thermoforming vaccum forming injection moldingChina manufacturer corrosion resistant PP sheet HDPE sheet for chemical industry and aquaculture

How PP Bubble Board Helps Automakers Reduce Vehicle Weight and Improve Fuel Efficiency

sourcehttps://www.polyreflex.com/

publisherPolyreflex

time2025/05/21

- Discover how PP Bubble Board helps automakers reduce vehicle weight and boost fuel efficiency. Learn about its lightweight structure, real automotive applications, and environmental benefits from Polyreflex.

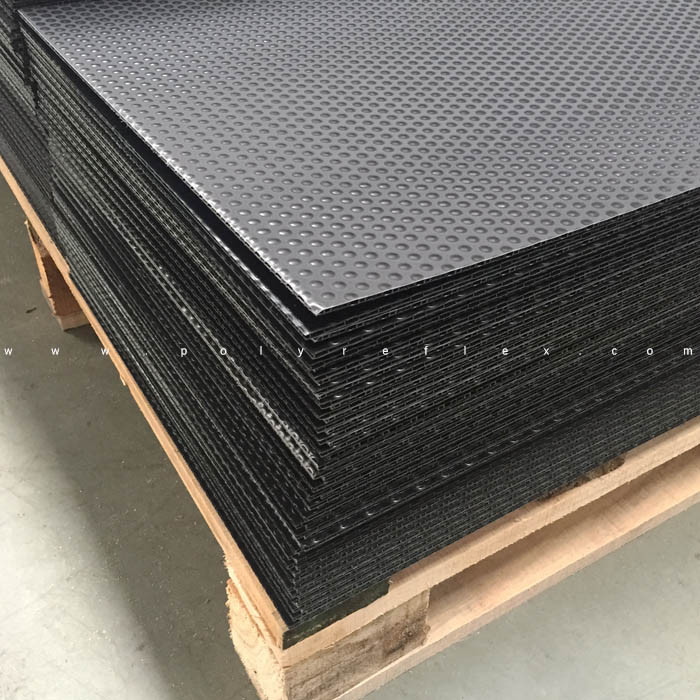

I. What Is PP Bubble Board?

II. Why Vehicle Lightweighting Matters

III. How PP Bubble Board Contributes to Vehicle Weight Reduction

| Material | Thickness | Approx. Weight |

| Plywood | 10mm | 6500g |

| Solid PP Sheet | 10mm | 8000g |

| PP Bubble Board | 10mm | 3000g |